PAGE 1

PAGE 2

(FOR MORE RECENT DEVELOPMENTS SEE

HERE)

DIY CONTROL LOADER COLUMN PROJECT

(Video Clips on

Page 2)

In the DIY force

feedback yoke pages I described an ongoing project to

build DIY force feedback flight sim controls. Although the overall

system seemed to work reasonably well one big issue was with

the smoothness of the force feel, and this

was due to the cogging or commutation ripple in shaft

torque produced by the electric motors used to power the

controls. I felt that the ripple spoiled the feel of the

force feedback.

I've now been able to try good quality disc armature motors1

in the system to take the project a step further. With these motors I think the quality of the

loading on the controls is greatly improved over the skewed

rotor servo motors I tried last time; generally the forces are

smoother and the motors offer little motion resistance when

operating at light force levels. The force feedback isn't

perfect however as some commutation disturbance in the motor

torque output is still discernable especially at higher force levels -

how significant individual users might think this is is an

interesting question! If I'm honest with myself I think it is noticeable.

The motors I've used are Mavilor MSS-4 DC servo motors

(below left). They are quite large and this has

prevented their use in the flight yoke setup so I've built a

simple flight column test rig to further work on the system.

The smaller MSS-2 motor in the same range might be a more

suitable choice for a yoke build - however not being sure of the

levels of torque performance needed I went for these bigger

motors for testing.

THE TEST FLIGHT COLUMN

The control loader flight column test rig is shown in the

image above right. You can see I've not spent much time

trying to make it look pretty - however it does function.

There are several features of the design that have turned

out to be important

in getting the force feedback system working and these are -

-

Rigid structural elements to minimise flexure of the

drive mechanism under load.

-

Low friction, well fitting pivots for both elevator and

aileron axis movements. The aileron axis is needle

roller bearing mounted, the column is pivoted at the

base on a steel pin mounted in close fitting steel

housings. I think ball bearings might further improve

things.

-

Toothed belt transmissions connecting the servo motors

to the column and yoke with belt tension adjustment to

ensure there is no backlash (slack) in the transmission.

-

Transmission shafts bearing mounted in rigid housings to

minimise friction and ensure constraint of any belt

pulley displacements which might lead to slackened

belts.

-

Precision position feedback potentiometers geared

without backlash to the movement axes. (The pots are

geared to utilise as much of their full electrical

travel as possible and are used with a 12bit joystick

card to generate the necessary resolution of position

feedback.)

|

Disc

armature DC servo motor |

It looks like all the above mechanical elements of the design are

necessary for acceptable performance of the force feedback

system. Any kind of lag, deadband, backlash or softness

anywhere between the accurate reporting of column movement

to the PC and the application of the force response from the

motors to the column will compromise the performance of the

system.

The need for this mechanical design/build performance is

matched by the need for similar levels of performance from

the electrical/control system and the force feedback

software. It is helpful to think of the

whole system as a chain of elements that needs to be

designed to minimse the time taken and maximise the accuracy

with which the column movement is detected and the force

response to this movement is applied to the column.

For information the elevator movement range of the test

flight column is roughly 300mm and the aileron axis rotation

is just short of +/- 90 Deg. The aileron drive has a 4:1

speed reduction between the MSS-4 motor and the yoke axis,

and the elevator drive has a 16:1 reduction made in two 4:1

stages. The elevator drive motor works harder than the

aileron drive and I think it might be possible to use a

smaller MSS-2 motor for the latter which would ease the

mechanical layout problems.

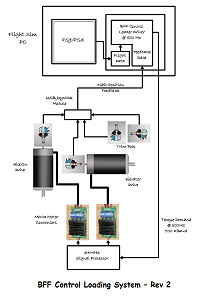

CONTROL SYSTEM & SOFTWARE

|

Improved

DIY force feedback system |

I've managed to improve both the electrical and control

system and the PC force feedback software. In particular

following my own experiments with the system and also

suggestions made by several emailers (thanks to all the

helpful suggestions emailed in) I've worked to increase the

refresh rate of the main force feedback to loop to 500 Hz.

Speeds higher than this are used in many commercial control

loader systems however an aim of the project was to try and

get reasonable levels of performance using low cost components.

This has not been possible regarding the motors because of

their critical role in the system, however I have

managed to keep the cost of the rest of the system down.

The force feedback software now does its load calculations

at a target 500 Hz. This is the limit of the 12 bit joystick

card (Leo Bodnar's) used to report control axis positions.

Note the feedback pots on the flight column are the same

ones FSX uses, but they need to be precision pots geared to

utilise their full electrical travel. Flight data from FSX/9 providing airspeed,

engine thrust, acceleration data etc is brought into the

calculations at the frame rate of the flight sim. The

calculated force demands are exported by the software using

500K baud serial comms and are processed by a new signal

processor unit based on the PICAXE 20X2 micro controller

running at 64 MHZ. The 500K baud comms is supported by the

standard FTDI chip based picaxe USB download cable (with

some serial port setting adjustments), and 64 MHz is a

standard speed for the 20X2 chip. The result is that the

voltage demands to the MD03 motor controllers on the I2C

data bus are refreshed at a target 500Hz.

The MD03 motor controllers use 8 bit resolution in their

motor voltage outputs, with their separate direction control

this gives torque demand over a range of nominally +/-255

steps.

This could be an issue if the system was set up to produce a

maximum force output that was much higher than the usual

working forces experienced during normal flight conditions.

So the 8 bit resolution does pose a limitation. I have the

test rig set up to try and match the maximum 255 demand

output to what I think are the max feedback forces

associated with flying at the normal airspeed limit of the

aircraft. This ensures that flight in the normal speed

ranges produces forces that use a good proportion of the

available 8 bit resolution and do not feel rough because of

the minimum step change in motor torque that can be

achieved. This is done by selecting the right voltage supply

for the MD03. The clear implication though is that trying to

set up a force range that includes very high failure mode

forces for example would probably make the feel at more

normal lower forces rougher.

The actual refresh speeds achieved by the system will be PC dependent. On my oldish

dual core AMD Athlon 64 6000+ machine I get slower refresh

speeds when running with FSX on the same PC when the force

feedback software is set not to hog CPU (I get about 350 Hz). I

have also written a LAN version of the software and using

this to run the force feedback system on an old single core

machine I get the full 500Hz as there is no FSX to compete

with. I suspect that a newer 4 or higher core machine might

be quite happy running both FSX and the force feedback

software - something to test.

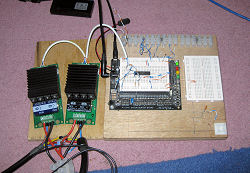

|

Motor

drive test set up with 64MHz signal processor unit

on breadboard |

The higher refresh speeds are required because they are important for some of the

components of the force feedback, but not all. The main

benefit is to reduce system lag when processing the

main control surface deflection related aerodynamic force

component. At lower refresh rates a greater delay is present

in how quickly the force responds to stick movement. If the

stick is moved fast enough the forcing can get sufficiently

out of phase with the motion to start to induce unstable

oscillations - this is not good! At the higher

refresh rates this does not happen and the stick response is

stable even if it is accidentally let go when in flight. See

- the video clips on

the next page.

Secondary, but still potentially important effects of the

higher refresh rates are to improve the effectiveness with

which speed of motion related damping can be added to the

stick response, and also how friction (or -ve friction) can

be simulated. I am finding that there are limits here

however, and although this low cost system seems to be able

to add moderate damping and friction effects the force feel

deteriorates if I overdo it and try to very heavily damp the

column movement through the dynamic model. One problem is that small commutation based

torque ripples from the motor result in small speed

fluctuations in the column motion which are then magnified

by a high speed related damping force gain in the closed loop. The frequency of these fluctuations is much higher

than the stick movements used for flight control and would

probably need a significant further uplift in the force

feedback loop refresh speed to remove the small system lag

causing the magnification. An alternative would be not to

use DC commutated motors - but both solutions would take us

further towards commercial control loader system specs and

the price tags associated with them.

So I think the system performs well for the price, but it

looks like there is a

firm limit to the capabilities of such low cost

electrical/control components.

Continued on page

2...... Performance and Video Clips

1. Many thanks are due to Don McKellow who

has kindly lent me the Mavilor disc armature motors to work

with. They are destined for Dons' full size B777 sim once

I've made enough progress on the system (assuming I don't

break them first). Don is a B777 training captain.

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at