For some other CL

system related images see the

Gallery

Some Customer Installations

Air Tractor Training Simulator (Alberta, Canada)

At the back end of 2014 I

supplied a 3-axis pre-assembled control loader drive

to

Western Air Spray in Canada.

It was installed in their new Air Tractor simulator

this year and saw initial service at a trade show

this spring (2015).

At the back end of 2014 I

supplied a 3-axis pre-assembled control loader drive

to

Western Air Spray in Canada.

It was installed in their new Air Tractor simulator

this year and saw initial service at a trade show

this spring (2015).

The system uses double stage chain reductions for

its transmission which work well but are reported by

the builder to be fairly maintenance intensive.

More details of

the build are provided on a dedicated web page

here....

Cessna 182RG Project (France)

|

Yoke mechanism with card enclosure

Motor driver cards and power supply in

enclosure... |

Here's a recent customer's implementation of

the DIY FFB Flight Yoke in a Cessna

182RG simulator in France. The yoke mechanism is located

behind the instrument panelling and the BLDRV-12/24 motor

driver cards are installed in the electrical enclosure next

to it.

Benjamin has done a great job on both the

mechanical and electrical build with a few subtle

modifications for belt tightening and structure stiffening.

He hopes soon to add an update on the system on his web site

here...

www.simu182rg.fr (site in French)

Heavy Jet Builds

The BFF control loader drive and

software isn't only suitable for use in the

DIY FFB Flight Yoke design

shown here. It can also be

built into other designs of flight controls. This includes

twin flight column setups typically seen in heavy jet

cockpits. Several customers have taken this approach and

implemented force feel in their heavy jet cockpits

(including in sims used for flight training).

The force output of the system is effectively

only limited by the design of the mechanical transmission

which connects the drive motors to the controls (although

good quality design and components are required so as not to

compromise the good force feel).

Below are a few examples....

Czech DC-9 Project

This

Douglas DC-9

cockpit restoration project is a work in progress in the

Czech Republic. The team intend eventually to add control

loading to all three control axes and at present the

elevator force feedback is up and running and integrated

with the original cockpit control mechanisms.

For more information see the Photos and

Videos sections of the

project's web

site.

The CL drive on the elevator uses a motor /

planetary gear head with crank arm to apply the force

feedback to the flight column. This is proving effective in

transmitting the loading without backlash into the control

mechanisms. The design target peak force in the elevator

axis is 20 kgf (44lbf) which is a fairly hefty load to

grapple with....

Here are a couple of videos from the team

showing first the elevator control loading in action, and

then some views of the under floor mechanisms.

The drive gear box aluminium crank arm can

just be seen at the back in this video....

Thanks to Pavel and Petr for allowing linking

to their movie clips...

SWESIM 737 Simulator

SWESIM

now have a 2 axis BFF CL system fully operational on their

737-800 simulator in

Sweden (web site in Swedish).

Theirs is a very interesting build also. They

have taken a different route to that described below for the

AERSIM project to the design of the mechanical

transmissions which connect the CL system brushless drive

motors to the flight controls. They have used a drive motor

with directly fitted planetary gear head and crank arm for

the elevator drive, and an interesting cable wire and pulley

drive to their aileron axis.

The gear head option provides a mechanically

simpler method than the belt pulley reduction units used by

Romek (see below) and is an attractive solution to consider so long as a good

quality gear head is used.

Here are a couple of YouTube videos showing

their system during build and commissioning...

This first video shows the flight control

mechanical assembly before installation - you can clearly

view the motors and transmission mechanisms - an interesting

build!

This second clip shows the system installed

and during setup and commissioning.

SWESIM reports that the system is

now fully operational and getting "very positive" feedback from real B737 pilots who

have tested the sim.

Many thanks to Erik at SWESIM for allowing me to link

to their site and videos.

|

AERSIM 747 Simulator |

|

Romek Delimata's Aersim 747 Simulator - fitted with

the BFF Flight Control Loading system. |

AERSIM 747 Simulator

The BFF flight control loading system has

recently been installed by Romek Delimata on his Boeing 747

simulator near Dublin.

Romek has designed his own drive mechanisms

to interface the brushless drive motors to his existing

elevator, aileron and rudder controls. A single brushless

motor is used to drive each axis of the dual-control set up.

The CL system consists of 3 BLDRV-12/24 cards

driving 3 brushless motors all instructed by the BFF CL

Software. The 747 sim runs FSX.

In addition to the normal variable force feel

and force trim effects to the simulator the CL system also

introduces believable vibration effects into all the

controls. Some of this vibration also transmits into the

airframe. The effect is to bring the controls alive with

variable vibration levels which reflect the level of engine

thrust or runway speeds.

Romek has also suggested adding spoiler

buffeting, other vibration effects such as landing gear air

buffeting would be worth considering.

Customer Comment: "The BFF force feedback

system is the biggest single improvement I've added to the

simulator in the 12 years I've been working on it, having

proper FFB provides a quantum leap in realism and makes it

far easier and more intuitive for professional pilots to

fly, the FFB provides all sorts of subtle yet very powerful

cues that really connect you with the forces acting on the

aircraft, in my opinion it's better then a motion system - I

can't recommend the BFF FFB system highly enough - well done

Ian on a ground breaking product."

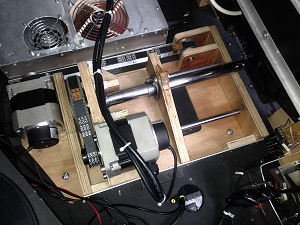

Here are a few photos showing some of the

drive setup - thanks to Romek for allowing me to

use these. The image below shows the elevator and aileron

mechanisms which are located under the floor of the sim.

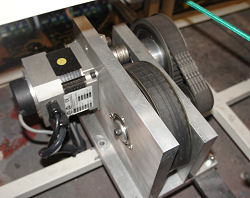

Both the elevator and rudder controls are

driven by a crank arm / connecting rod arrangement. The

connecting rod connects a short crank arm on a 2 stage belt

reduction unit to a longer crank arm added to the existing

elevator pivot mechanism. A similar efficient back-driveable

reduction could be achieved using a planetary gearhead

mounted on the motor.

|

|

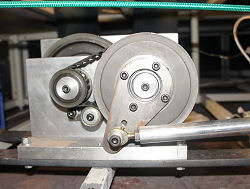

|

FFB Drive Crank Mechanism details |

The aileron control axis is driven by roller

chain to which the aileron axis brushless motor is

interfaced.

You can see some of the aileron roller chain

in the image left - the chain loops up each flight column to

the control wheels. The whole of the aileron drive mechanism

is mounted on the pivoted elevator assembly.

Unfortunately the rudder pedal drive

mechanism is snugly fitted under the panel area and can't be

seen all that clearly in photos. However it utilises an

identical 2 stage belt reduction unit and crank arm to drive

the existing dual pedal mechanism to produce the force

feedback.

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at