Previous

Contents

Next

Appendix J.

CL Controller App - Input UDP Data Format

|

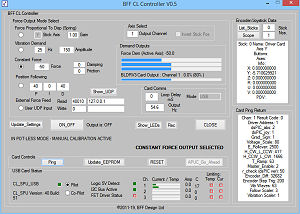

BFF CL Controller

software

DOWNLOAD:

Now included in main CL software download

USER GUIDE:

Quick User Guide |

The

CL Controller is a new

app which combines the loading test functions available in

the Driver Test App with a new operating mode which accepts loading command data from 3rd party

apps via UDP.

This allows 3rd party apps to

control the CL drive cards via the CL Controller. Applies to

CL_SPU_USB and BLDRV3 cards only.

NOTE the CL Controller can not

drive the same CL_SPU_USB card at the same time as the main CL

Software. So if the CL Software AND the CL Controller are to be used

at the same time then two CL_SPU_USB cards with their own BLDRV3

drives are required.

Installation:

The CL Controller is included in

the main CL software download zip in the Driver Test App folder.

Operation:

NOTE: if the CL Controller is

being used to provide specialised axes at the same time as the main

BFF CL Software is driving the main control axes then the CL

Software CL_SPU_USB card should be jumper set as "Pilot", and the CL

Controller should connect to the jumper set Co_Pilot CL_SPU_USB

card. Parameter CP_Ignore should be set =1 in the Background.ini

file to instruct the main CL Software to then ignore any Co-Pilot

CL_SPU card.

The CL Controller should be

running and the UDP Input radio button selected to make the UDP data

mode active.

When running in UDP input mode, the

CL Controller will

listen for UDP data on the Port and IP Address specified in the

CL_Controller ini file (also shown on the GUI). You must write your own application to send valid

loading data. The data format is shown below.

WARNING - Improperly

formatted or controlled user loading input data can produce erratic

or uncontrolled force and movement outputs at the driven flight

control motors - you must thoroughly test your UDP data "feeder" application before

making the card output live to connected flight controls.

Use the progress bar displays on

the CL Controller to monitor the output force demands that result

from your Feeder application before driving live flight controls. A UDP data view window is also provided to allow visual inspection of

received data packets.

UDP Data Formats:

When in UDP Input mode the CL

Controller looks for loading control data in 180 byte packets

received by UDP on the Port and IP Address specified in the

CL_Controller.ini config file (parameters Port

and IPAddress in the [Comms] section).

The CL Controller will return a 50

byte response packet on each input packet receive. This UDP return

will be via port Port+1 to the IP Address and Port specified

by the feeder app within the 180 byte input packet.

The 180 byte input packet format is:

| Byte

Offset |

Name |

Type |

Description |

| 0 |

Packet

ID |

UInt |

Each data packet should have a

unique +ve integer ID. Usually this is a simple indexing

packet counter. |

| 4 |

Loading

Engage Command |

UChar |

=0 loading disengage, =1 loading

engage Note these will be

overridden by the Engage/Disengage button on the CL

Controller.

On the ON/OFF transition the CL

Controller will ramp up/down the loading.

On the ON transition CL Controller

will also ping the cards to determine status before ramping

up the loading - this will cause a momentary delay to the

load engage. |

| 5 |

Feeder

PC IP Address |

15 byte

String |

IPV4 format IP Address of the

Feeder App's network location to which the 50 byte return

packet will be sent. If the Feeder App and CL Controller App

are running on the same PC then this can be a loop-back

address, eg 127.0.0.1 Pad

unused trailing bytes with NULLs |

| 20 |

Return

Port |

UShort |

Port to which the return packet

will be sent.

=0 to disable the return packet

send. |

| 22 |

Position Following Engage |

UChar |

Position Following Engage

Bitwise as follows:

bit0 - enable axis 1 position following, 0 = off, 1 = on

bit1 - enable axis 2

bit2 - enable axis 3

bit3 -

bit4 -

bit5 - position following ALWAYS-ON for all axes (eg for

Slave station

operation)

bit6 - (heli-trim on/off)

bit7 - (enable heli-control mode) |

| 23-29 |

Spare

Bytes |

|

pad with NULL |

| |

|

|

3 x 50 byte sections follow; 50

bytes for each loading axis.

Axis 1 (Elevator) |

| 30+0 |

Fixed

Force |

Float |

Fixed force component: +/- 100%

+ve is drive in +ve drive direction of

card/motor |

| 30+4 |

Spring

Force Coefficient |

Float |

Spring force component as

stiffness coefficient: typically 0-10.0

A Coefficient of 1.0 will generate

100% force at 100% deflection. Only +ve values allowed and

will generate a force opposing displacement -ie always a

return to mid position. |

| 30+8 |

Friction Coeff |

Short |

+/- 127, typically in range +/-10.

+ve to oppose movement |

| 30+10 |

Damping

Coeff |

Short |

+/- 127, typically in range +/-10.

+ve to oppose velocity |

| 30+12 |

Vibration Channel 1 Base Freq (Hz) |

Short |

5-100 typically

Channel 1 is an engine mix |

| 30+14 |

Vibration Channel 1 Amplitude |

Short |

5-100 typically.

Vibration mix is

also scaled and defined by card EEPROM settings |

| 30+16 |

Vibration Channel 2 Base Freq (Hz) |

Short |

5-100 typically

Channel 2 is a runway mix |

| 30+18 |

Vibration Channel 2 Amplitude |

Short |

5-100 typically.

Vibration mix is

also scaled and defined by card EEPROM settings |

| 30+20 |

Vibration Channel 3 Base Freq (Hz) |

Short |

5-100 typically

Channel 3 is a stall mix |

| 30+22 |

Vibration Channel 3 Amplitude |

Short |

5-100 typically.

Vibration mix is

also scaled and defined by card EEPROM settings |

| 30+24 |

Position Following P Term |

Short |

0-127.0 typically 20 to 60

Proportional term of position

following PID algorithm |

| 30+26 |

Position Following I Term |

Short |

0-127.0 typically not used in CL

drives (use 0.0) Integral term of

position following PID algorithm |

| 30+28 |

Position Following D Term |

Short |

0-127.0 typically 20 to 60

Derivative term of position following

PID algorithm |

| 30+30 |

Position Following Set Point |

Float |

0-100.00%

Demanded position when in position

following mode. Mid position is 50%, full displacement in

drive direction is 100%

(Corrected 5/20,

previously stated as +/-100% range) |

| 30+34 |

Breakout Rate |

UChar |

Integer value 1, 2, 3 or 4

Sets the onset rate of the breakout

force |

| 30+35 |

Breakout Amplitude |

UChar |

0-100 typically 10-20

Sets the magnitude of the breakout

force |

| 30+36 to

+49 |

Spare

Bytes |

|

pad with NULL |

| |

|

|

|

| 80+0 to

+49 |

As

Above |

|

Repeat for Axis 2 (Aileron) |

| |

|

|

|

| 130+0 to

+49 |

As

Above |

|

Repeat for Axis 3 (Aileron) |

UChar = 8 bit (1 byte) unsigned integer (value

0-255)

UShort = 16 bit (2 byte) unsigned integer

Short = 16 bit (2 byte) signed integer

UInt = 32 bit (4 byte) unsigned integer

Int = 32 bit (4 byte) signed integer

Float = 32 bit (4 byte) floating point number

The frequency of data packets

should typically be about 50Hz to match the command rate of the CL

Controller to the drive cards

You should experiment to obtain processing rates to suit your

application. If the data packets arrive faster than the CL

Controller can process them it will simply drop unused packets.

The UDP_Display button on the GUI

can be use to display the incoming UDP data.

UDP Return Packet Format:

The CL Controller will return a 50

byte response packet on each input packet receive. This UDP return

will be via port Port+1 to the IP Address and Port specified

by the Feeder app in the 180 byte input packet.

The 50 byte return packet format is:

| Byte

Offset |

Name |

Type |

Description |

| 0 |

Packet

ID |

UInt |

Each return data packet has a

unique +ve integer ID. This is a simple indexing

packet counter. |

| 4 |

Last

Input Packet ID |

UInt |

Packet ID of last used 180 byte

input packet |

| 8 |

Force

Enable Status |

UChar |

Current loading ON/OFF status.

0 = OFF, 1 = ON |

| 9 |

Drive

Axis 1 Status |

UChar |

dsPIC_Joy1 status byte

=0 - axis not calibrated

=1 - axis calibrated

=3 - axis has moved out of calibrated range

>= 4 - unknown dsPIC_Joy error |

| 10 |

Drive

Axis 2 Status |

UChar |

dsPIC_Joy2 |

| 11 |

Drive

Axis 3 Status |

UChar |

dsPIC_Joy3 |

| 12 |

Card

Auto-Calibration Status |

UChar |

Bit significant -

bit0 - MUST = 0 for bits below to be active

bit1 - ELEV awaiting APUC go-ahead

bit2 - AIL awaiting APUC go-ahead

bit3 - RUD awaiting APUC go-ahead

bit4 - ELEV APUC movements in progress

bit5 - AIL APUC movements in progress

bit6 - RUD APUC movements in progress

bit7 - 0 |

| 13 |

Card

Condition |

UChar |

Bit significant -

bit0 - 0

bit1 - ELEV card is over-temperature limiting

bit2 - AIL card is over-temperature limiting

bit3 - RUD card is over-temperature limiting

bit4 - ELEV card is over-current limiting

bit5 - AIL card is over-current limiting

bit6 - RUD card is over-current limiting

bit7 - 0 |

| 14-16 |

Spare

Bytes |

|

NULL |

| 17 |

Axis 1

Position |

Float |

Axis 1 position in range +/- 100%,

mid = 0 |

| 21 |

Axis 2

Position |

Float |

Axis 2 |

| 25 |

Axis 3

Position |

Float |

Axis 3 |

| 29 |

Axis 1

Torque |

Float |

Axis 1 torque in range +/- 100%

(of available output after card internal voltage scaling) |

| 33 |

Axis 2

Torque |

Float |

Axis 2 |

| 37 |

Axis 3

Torque |

Float |

Axis 3 |

| 41-45 |

Spare

Bytes |

|

NULL |

| 46 |

Packet

ID Repeated |

UInt |

See offset 0 |

Test Feeder Application:

The download zip package contains

a test "Feeder" application which can be used to confirm UDP comms

with the CL Controller. The Feeder application can pull position

data from the x, y & z axes of the joystick specified in the

Sender.cfg file and use this to set

load or stiffness components to send to the CL Controller. It

will send the data to the CL Controller using correctly formatted UDP packets. If UDP comms are

active the data will appear at the CL Controller....

The test Feeder app will also

display returned response packets from the CL Controller if the UDP

comms are correctly configured.

The port and IP address settings

for the Feeder should be made in the Sender.cfg file.

This is intended for checking

UDP comms only - DO NOT use this facility to control live flight

controls.

Demonstration Steering Tiller Feeder Application:

A demonstration feeder app is also

provided in the download zip which provides simple loading for a

heavy jet steering tiller axis.

Further information here....

Comments:

The data components used in the

data packets are designed to suit control loader type applications.

In particular the spring rate parameter (spring force coefficient)

should be used when loading proportional to control displacement is

present. The fixed force parameter should be used for slower

changing forces only. In order to maintain stability in the drive it

is important to minimise lag between axis position changes and the

responding torque demand applied to the motors when there is

a possibility that the position can change rapidly. The most

critical type of loading in this regard is force that changes

directly with stick displacement such as aerofoil lift forces. By

using a spring rate term the critical calculations for this type of

loading can be carried out onboard the BLDRV3 cards and so minimise

the lag between position feedback and torque response. These onboard

calculations are carried out once every 2ms (ie at 500Hz) and ensure

that the torque demand output "keeps up" even with fast changing

stick position and so ensures stability of the drive by preventing

unstable oscillations from developing.

The principal applies to other

applications in which there is a significant force component which

changes directly in response to axis position change.

Updates:

V0.91 adds a new window which

displays monitoring data for the APUC movements of the controls.

This requires recent BLDRV3 card firmware to operate.

If you find any bugs or strange

behaviours in the beta version then please let me know.

Previous

Contents

Next

|