DIY Motion Platform Servo Drive System -

64SPU-1 Card

|

NOTE An

un-programmed version of the 64SPU-1 is now

available for use in your own DIY electronics

projects.

More details here |

UPDATE March 2015, IMPORTANT - the

64SPU-1 has now been superseded with the NEW

64SPU-2 card - see here for more

details.

UPDATE March 2013, for an excellent

example of a drive system build using the 64SPU-1 and other

cards please see Roland van Roy's write-up here -

http://simprojects.nl/electrical_drive_iv.htm

Roland has helpfully provided advice and

his technical wiring diagrams for his system on the page.

The motion platform servo drive system

developed for the DIY platform projects described on the web

site has evolved through several versions to what is now a

compact and effective low-cost DIY motion platform servo drive. The

home-made

Signal Processor Units I previously built on a PICAXE

breadboard kit have now been replaced with a small standalone

PCB that incorporates all the previous features of the SPU's and adds

several important enhancements. The 64SPU-1 card is

available to buy now.

The 64SPU-1 card works with the

BFF PID Servo Controller software

to provide a functioning servo control system.

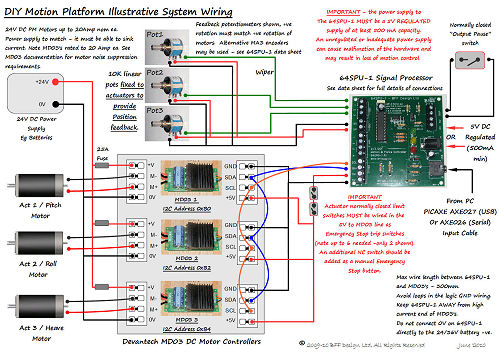

Illustrative system wiring below: (for

use with alternative Dimension Engineering Sabertooth /

SyRen controllers see here...)

|

|

Optional Cards

BFF I2C Isolator card

For noise protection of the

64SPU-1 on electrically noisy servo systems.

12ADC-1 12bit pot

feedback converter card - upgrade to 12bit

feedback resolution. |

The main components that make up the DIY motion

platform servo drive are

now:

-

The 64SPU-1 64MHz Signal Processor Unit

card - available to buy now - see the order pages

here.

-

Devantech

MD03 Motor Speed Controllers - 24V 20 Amp DC

controllers delivering up to 480 Watts of electrical

power per controller.

-

24V DC PM Motors to suit the DIY

platform project. The MD03 controllers will support up

to a nominal 20 Amps rating, sustained currents above this

level will cause overheating and current limiting by the

MD03's.

-

Position feedback potentiometers (10

bit), or, recommended for smoother drives, the

12ADC-1 12bit ADC card or US Digital

MA3 position encoders (12bit PWM). (Pots/encoders fitted to the

drive actuators or elsewhere on the platform to report

actual platform position.)

-

DC power supplies for the drive motors

and electronics.

-

Actuator travel limit switches, fuses,

cables and wiring.

PLEASE NOTE - I am not able to supply all of

the above hardware, just the 64SPU-1 card, the

BFF I2C Isolator card ,

12ADC-1 12bit ADC card and motion

software. If you want to build the servo drive for your own

project then you will need to source the motors,

controllers, encoders, switches etc etc yourself.

IMPORTANT - The 64SPU-1 card is part of a

closed loop position feedback servo drive. The position

feedback potentiometers/encoders shown on the wiring

diagrams MUST be fitted to the drive motors/actuators to

report platform position to the 64SPU-1 card. Without this

the closed loop position control can NOT operate. If you are

not sure what a closed loop position control servo drive is

then I recommend you try and read-up a bit before attempting

to use this hardware. It is very important to understand

that this is not a "plug and play" system intended for

consumer use - it is intended for use by informed DIY system

builders. Read both the motion software user manual and the

64SPU-1 data sheet before using the hardware.

|

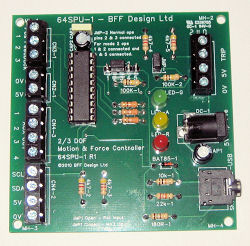

64SPU-1 Signal Processor Unit

For DIY Motion

Platform DC Servo Drives |

64SPU-1 Card - The new

64SPU-1 signal processor card is at

the heart of the servo drive and acts as the

communications bridge between the MD03 motor controllers, feedback pots/encoders and the BFF PID Servo Controller

software running on the PC. It also acts as a system

monitoring and information feedback unit - it monitors for

communications interruptions and stops the motor drives when

required and also

feeds back MD03 current and temperature information to the

Servo Controller software.

The 64SPU-1 is available to buy as a

ready-to-connect card (80 mm x 80 mm) which removes the need for all the

delicate breadboard wiring of the

previous DIY versions.

For full details read the 64SPU-1 data sheet

-

64SPU-1 Data Sheet

The main features of the 64SPU-1 are:

-

I2C data output for use with Devantech MD03 motor speed

controllers.

-

2 or 3 channel output for 2 or 3 DOF motion systems.

-

Selectable Potentiometer (10 bit) or MA3 Digital Encoder

(12 bit) actuator position feedback. Potentiometer

feedback can be upgraded to 12bit resolution using the

12ADC-1 card.

-

Built-in fast smoothing on the potentiometer feedback to

reduce signal noise. Use with the

12bit 12ADC-1 card for best potentiometer feedback

smoothness.

-

Built-in “Pause Output” or "Drive Enable" trip loop.

-

64MHz operation giving up to 50Hz control loop refresh

speeds (up to 70Hz when used with the

12ADC-1 pot feedback card).

-

Direct connection to PC USB or Serial port (physical

serial port recommended for fastest speeds). 115200 baud

serial comms.

-

LED status indicators, screw connectors.

-

On-board 20X2 microcontroller re-programmable in-situ

for firmware upgrade or customised output programming.

The card is available to buy on its own or bundled

with the V2 Motion Driver software -

see the order page here.

(NOTE - Data Sheet for superceded 40SPU-1

card can be found

here...)

SERVO SYSTEM OPERATION

|

40SPU-1 and

MD03 motor

controllers on

test |

The servo system hardware works in

conjunction with the BFF PID Servo Control software running on

the PC.

The servo software receives platform position demand

information from the BFF Motion Driver and

also receives actual platform

position feedback data from the position feedback

pots/encoders connected to the 64SPU-1 card. Using this data it calculates

motor speed demand outputs which control the direction and

speed of the actuator drive motors to drive the

platform to the demanded positions. The motor control

commands are sent to the MD03 motor controllers via the

64SPU-1 signal processor card.

The servo control loop can run at up to 50Hz

(PC and connection dependent) - ie the speed and direction of each motor is

adjusted by the system up to 50 times each second and this

makes for an effective system response under most platform

motions. For the best performance it is better to run the

motion software on a LAN PC separate from the flight sim PC.

If the 12ADC-1 12bit potentiometer

feedback converter card is used the servo loop can run at up

to 70Hz.

|

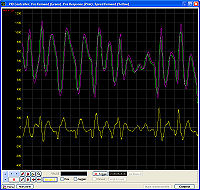

An example

actuator trace

(using the PID

Controller's built-in

virtual

oscilloscope). |

The servo software uses a PID (proportional -

integral - derivative) control algorithm and the PID

parameters that define the control response can be set through the BFF Servo Controller GUI.

This makes tuning the servo system easier as small changes

can be made to the control algorithm and the resulting

effects on the motion assessed immediately.

Actuator limit switches and an Emergency Stop

switch should be wired in series in the 5V supply line from

the 64SPU-1 to the MD03 motor controllers to cut the drive

to the motors to prevent damage if the actuators over-stroke.

The 64SPU-1 also includes a simple trip loop into which a

"Pause Output" or "Drive Enable" switch can be wired.

Motor controller "live" current and

temperature data is continuously fed back by the 64SPU-1 to

be displayed on the PC by the BFF Servo Controller software.

This makes for interesting viewing, however it can also be

of significant assistance during platform set-up work as it

provides a

direct indication of the system electrical loading. The servo software also

includes a virtual

oscilloscope to view demanded and actual actuator positions

and motor speed demand.

|

Video clip of

the older 40SPU-1

driving the

Mini Motion

Platform. NB

The platform is being driven with no pilot load

so against the unbalanced force of the support

column spring. |

For the best performance of the servo drive I

find that 12bit position feedback (using either

MA3 absolute position encoders

or pot feedback via the 12bit 12ADC-1

card) should be used for the

position feedback, and the 64SPU-1 should be connected to the

driving PC through a physical Serial (COM) port. If you are

using the PICAXE USB Serial cable then it also can give good

results by reducing the "Latency Timer" setting to 1 ms in

the relevant COM port's advanced settings.

Overall the 64SPU-1 and associated servo

software can provide an effective servo drive for DIY motion

platforms at a seriously low price. The 64SPU-1 is however a

relatively simple card and although it contains a number of

safety features such as comms time-out monitoring, some

feedback error detection and feedback limit detection the

price does not allow the types of system monitoring

capabilities that can be found on much more expensive commercial motion

controllers. You must take care to ensure the platform

drive is properly protected by over-travel limit switches

and an accessible Emergency Stop button.

Although there are some electrical noise

isolation features on the card in particularly electrically

noisy systems the on-board 20X2 microcontroller can be

affected by voltage spikes coming through on the 5V and

ground lines. The source of such electrical noise is usually the

drive motors. For added reliability the

BFF I2C Isolator card can be

used with the 64SPU-1 to fully isolate it from wiring bourn

noise propagating from the electric drive motors through the

MD03 logic ground connections. The

isolator card allows the

64SPU-1 to be powered from its own independent clean 5V

power supply.

If you wish to buy the 64SPU-1 please read

the data sheet

carefully and follow the installation and use

recommendations.

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at