Previous

Contents

Next

12. PID Servo Controller 12. PID Servo Controller

12.1

Configuration File Settings

12.2 Operation

12.3 PID Control Settings

12.4 PID Control Settings - Setup Procedures

The BFF

PID Servo Controller and 64SPU-1 hardware

card operate together to form the core of a motion platform

closed loop electric motor servo drive. The software and hardware

support up to three output channels.

The PID

Servo Controller software converts the motion cue output from the

BFF Motion Driver software into motor speed and direction demands

which are used to drive the electric motors via motor speed

controllers. The software will not

operate unless it is connected to an active and properly configured

64SPU-1 signal processor card (or other valid SPU). For full details of the 64SPU-1 read

the

card data sheet.

The PID

Servo Controller is installed as part of the motion driver software

package. It is run using the Start_PID_Controller button on

the BFF Motion Driver window.

The

software communicates with the 64SPU-1 hardware using serial comms

via either a physical or virtual COM port. If the PICAXE AXE027

download cable is used speed can be improved by adjusting the

Latency Timer setting for the virtual COM port to 1 ms.

To do this go to Control Panel

- Device Manager and open the COM ports section. Double

click on the AXE027 entry and then select Port Settings -

Advanced and in the BM Options area set the

Latency Timer to 1 ms. You may have to try different

settings to get the best setting for your system.

12.1

Configuration File Settings

Motion

Driver Settings (in .bff config file)

To use the

PID Servo Controller the data output mode of the motion driver must

be set to Mode=MEM. This instructs the motion driver to make

the cue data and other settings available to the PID Servo

Controller through a shared memory area.

The

Port=COM* parameter should be set to specify the com port the PID Servo

Controller should use to communicate with the external 64SPU-1 card.

PID

Servo Controller Settings (in PID26.cfg file)

The

controller software's local settings are held in the PID26.cfg file.

A few settings must be made in the PID26.cfg manually using a

text editor such as NotePad. In normal use the .cfg file does not

need to be accessed manually - the software reads and writes

settings as required.

The

PID26.cfg contents are shown below (comments in blue are NOT present

in the file):

-----------------------------------------------------------------------------------------------------------------------------------------

1. 30

;Start of PID Settings - do not adjust in file

2. 1.0

3. 0.05

4. 0

5. 30

6. 1.0

7. 0.05

8. 0

9. 30

10. 1.0

11. 0.05

12. 0

13. 20

14. 1.0

15. 0.05

16. 0

17. 20

18. 1.0

19. 0.05

20. 0

21. 20

22. 1.0

23. 0.05

24. 0

;End of PID Settings

25. 0

;Feedback noise filter on/off - it is best to use good quality

feedback devices rather than the software filter

26. 0.05

;Noise filer Time Constant

27. 0

;Data trace

28. 115200

;64SPU-1 comms baud rate

29. 00111011

;64SPU-1 bit settings - see 64SPU-1 data sheet Section 3

30. Built-For-Fun EVs - 3-DOF Cockpit Motion

Driver v2

;Title of Motion Driver window

31. I2C

;Data output format identifier

32. COM2

;Dimension Engineering Sabertooth controller comms COM port

33. 38400

;Dimension Engineering Sabertooth controller comms baud rate

34. 128-1

;Sabertooth channel 1 address

35. 128-2

;Sabertooth channel 2 address

36. 129-1

;Sabertooth channel 3 address

37. Normal

;PID Servo Controller Sabertooth comms process priority

38. Yes

;Enable polynomial cue data use

39. Normal

;PID Servo Controller process priority

------------------------------------------------------------------------------------------------------------------------------------------

Lines

10-24 contain the individual PID settings for each channel - these

should not be adjusted in the file. The software reads and writes

these directly.

Lines 24 &

25 define the software noise filtering of the position feedback

data. This is retained as a legacy setting - it is better just to

use good quality feedback devices.

Line 27 is

data trace output setting, =0 for off, =1, 2 or 3 to output data for

numbered channel. Data is written to file PID_Output.txt each data

loop so the output will build up very quickly if left on -

use for short bursts only.

The data items are: Position feedback, Demanded position, Position

error, P, I & D speed demand terms, Total speed demand, Controller

current, controller temp. The data can be inspected and charted in a

spreadsheet application.

Line 28,

the 64SPU-1 baud rate must be left at 115200

Line 29, 8

bit control settings for the 64SPU-1 - see the

64SPU-1 data sheet

Section 3.

Line 30,

motion driver window title - leave as is.

Line 31,

data output mode, = "I2C" for MD03 drive from 64SPU-1, = "SERIAL2"

or "SERIAL2x25" for Sabertooth controller output - see

Sabertooth Quick Start Guide for details.

Lines

32-36, Sabertooth setup settings - see

Sabertooth Quick Start Guide for details.

Line 37,

Sabertooth comms process priority, = Normal, High etc. This can be

used to give the Sabertooth comms process better access to system

resources if it is running on the same sim PC as the flight sim and

is struggling to produce smooth output.

Line 38,

best to leave as is - this enables the servo controller to use

position demands sent from the motion driver as polynomial curve

fits. This gives smoother interpolation and smoother D term

behaviour.

12.2 Operation

The

PID Servo Controller will only run properly once your 64SPU-1 card

has been connected and configured. See the

64SPU-1 data sheet

for details for the card setup. The

PID Servo Controller will only run properly once your 64SPU-1 card

has been connected and configured. See the

64SPU-1 data sheet

for details for the card setup.

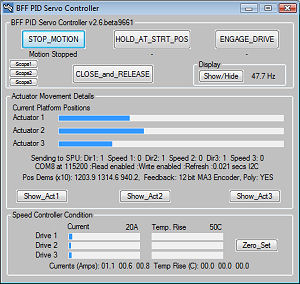

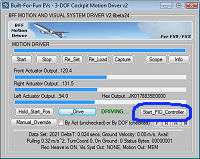

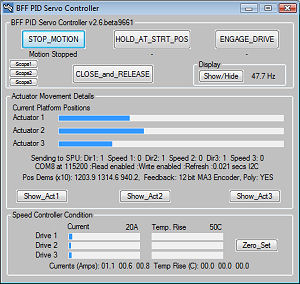

To run the

PID Servo Controller start the BFF Motion Driver and once it is

running and in Hold mode select the Start_PID_Controller

button.

The PID

Servo Controller will start and try to communicate with the 64SPU-1

card - check the messages in the text area of the window. If the

comms are established successfully the software will report the

current actuator positions, servo loop refresh speed etc. The

64SPU-1 LEDs will also change to running status if the comms are

operational - see the

64SPU-1 data sheet for details.

PLATFORM START PROCEDURE

1. With

Motion Driver on Hold, select servo controller

HOLD_AT_STRT_POS - to move the platform to its park/hold

position.

2. Select

ENGAGE_DRIVE to make the servo drive active for cue

following.

3. Now use

the Hold_Start_Pos and Drive buttons on the motion

driver to move the platform smoothly between Hold and Drive modes as

required.

PLATFORM STOP PROCEDURE

1. With

the servo drive still engaged use the motion driver Hold

button to move the platform smoothly to park/hold position.

2. Select

the servo controller HOLD_AT_STRT_POS to fix the platform at

park/hold position, and when required select STOP_MOTION to

stop the drive.

In

STOP_MOTION mode the servo drive will request zero speed from

the motors. When CLOSE_and_RELEASE is selected the software

stops sending speed demands and closes. Note that the motor speed

controllers may not release the zero speed demand on the speed

controllers until they are powered-down.

The

Show/Hide button is used to minimise the display - this reduces

CPU load and lifts refresh speed slightly.

Scope*

buttons to show/hide the built-in oscilloscope for the chosen

channel.

The Speed

Controller Condition area shows live feedback of MD03 motor

controller current and temperature. It is only active if MD03's are

present and readback is enabled in the PID26.cfg file. The values

are relative - use the Zero_Set button to zero them at

startup. They provide a useful visual monitor of controller

condition.

12.3 PID Control Settings

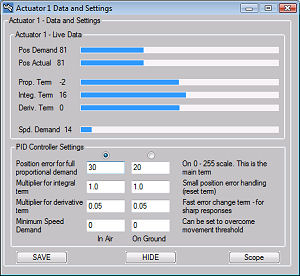

The

Show_Act* buttons are used to display the control details for

each channel and to set the PID control parameters.

The

individual components of the speed demand output are displayed in

the upper window area. In the lower area the PID settings are shown. The

individual components of the speed demand output are displayed in

the upper window area. In the lower area the PID settings are shown.

There are

two sets of PID settings - one for in-air operations and one for

on-ground operations.

WARNING - changing the PID settings can

make the drive unstable - take great care when making changes and do

so by making small adjustments only. DO NOT make changes to the

settings whilst the platform is in motion, stop the motion first

using the HOLD and STOP buttons. Test changes by first

using the HOLD_AT_START_POS button to instruct the system to

hold position before moving on to full drive with the new settings.

Position Error for full proportional

demand

The

position error that gives full speed demand. If the instantaneous

error is below this value the speed demand is scaled down if it is

above this value the speed demand holds at maximum. The smaller the

value is the faster the platform movement will respond to changes in

the demanded position. However the smaller values will also mean it

has more trouble slowing to a stop once the rig has moved to the

demanded position. So small values give fast response with likely

position overshoot, and large values give slow smooth response with

no overshoot.

Values between 20 and 100 as a guide

only - set with reference to the specified feedback range for the

actuator.

Multiplier for Integral Term

Also know as the re-set term, this calculates a

contribution to the speed demand based on how long a position error

is sustained. It is mainly of use for making sure that the position

comes back to that demanded when the proportional term has lost its

effect on small position changes.

Guide values would be from 0 to 4 or 5.

Multiplier for

Derivative Term

The trickiest term to get right. This speed demand

component is calculated from the rate at which the error is

changing. If the rate is high it means that the actual and demanded

positions are either moving apart quickly or coming together

quickly. If they are moving apart quickly the rig isn't moving fast

enough and the D term gives a boost to the speed, if they are coming

together quickly the rig needs to slow down faster and the D term

acts as a brake on the motion. The practical effect can be as a

brake and to help to reduce the extent of any overshoot there may be

if the proportional term is set to respond strongly to position

errors. Its use is therefore likely to be able to allow faster

response Proportional terms to be used by reducing the extent of the

associated overshoot. It can also be used simply to enhance the

response to events such as touch-down bumps when a slow proportional

response is being used.

Guide values would be from 0.01 to 0.2 - depends

strongly on feedback resolution and quality, use 12bit feedback from

the 12ADC-1 card for best effects.

Minimum Speed Demand

This is an additional term which

allows a small fixed speed demand to be added in to the total to

help overcome any friction based movement threshold in the system.

Setting this just below the speed demand that actually initiates

movement may help improve the speed of response.

Guide values, 0 to 20.

12.4 PID Control Settings -

Setup Procedures

Unfortunately there is no set of

settings that will be correct for every motion platform. Many of the

above variables need to be set experimentally. Start by setting the

Integral and Derivative terms to zero and work with the Proportional

term first. This should be set at the higher end of the guide scale

and then reduced gradually until the rig motion in response to step

position inputs starts to overshoot or oscillate.

If you wish to make use of the

Minimum Speed Demand setting, set this next. With the Servo

Controller holding mid position increase the setting from zero until

the movement starts to oscillate slightly – do it in small steps. A

setting which holds the motion steady but just “ready” to move is

what you are looking for. If this is set too high you will feel a

“clunk” each time the platform drive changes direction.

The Integral term can also be set

with the controller holding position. Increase the values in small

steps until you start to see small oscillations occurring. Watch the

progress bars – you will see the integral term building until a

small movement adjustment takes place and the term reduces again.

The Derivative term will be the

hardest to get right. If you feel it is not needed then don't use it

– set it to zero. Again increase the setting in small steps from

zero and watch the response of the rig before going on to see if you

can then further reduce the Proportional term error setting. You

will see the D term progress bar start to jitter as the D term is

increased, this will give an indication of the limit of

applicability with your feedback quality.

ALWAYS

TAKE CARE – ADJUSTING THE CONTROL SETTINGS CAN CAUSE RAPID MOVEMENT

OF THE PLATFORM. ENSURE SAFETY PRECAUTIONS ARE TAKEN AND ENSURE THE

PLATFORM TRAVEL LIMIT SWITCHES AND ACCESSIBLE EMERGENCY STOP BUTTON

ARE FITTED AND FULLY OPERATIONAL.

Previous

Contents

Next

|