DIY

OpenBeam FFB Flight Yoke

UPDATE Nov '18 - 3D Printing stl

files now added for adaptor parts to allow 60ST-M01330

motors to be used in the yoke.

UPDATE Jan '17 - More

detailed plans now added here.

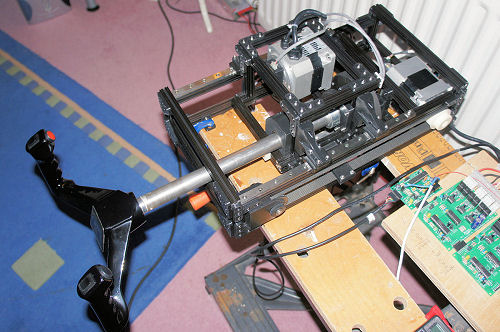

This force feedback flight yoke provides an alternative build

approach to the original timber

structure CL yoke shown here. It will be of interest to

builders who do not want or aren't able to get into making individual

components from timber or metal.

The yoke's framework is assembled from

OpenBeam

aluminium extrusions, with other brackets and components

3D printed.

|

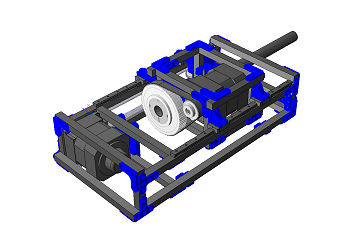

DIY CL Yoke - constructed from OpenBeam beams

and 3D printed parts |

The drive motors and transmission

specifications are more or less the same as for the timber

yoke, as is the force performance.

Like the original timber version, this OpenBeam

FFB yoke is designed to be installed behind the sim

instrument panel; it is not intended as a desktop device.

The OpenBeam system offers a flexible way of

building structures but I was initially concerned that the 15mm

square OpenBeam extrusions might not be rigid enough to deal

with the forces developed by the drive motors. However the

framework

has proved surprisingly rigid on its own, and when secured

to a solid support structure it is perfectly adequate for

operation - the control wheel feels solid in use.

|

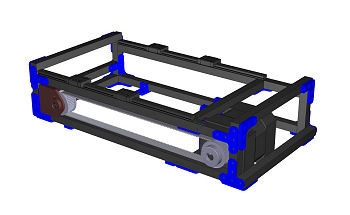

Base - Frame with elevator axis drive and linear

guides for supporting the moving carriage |

The 3D printed components - belt pulleys,

bearing housings and various brackets have also proved

effective. Their strength and accuracy depends off course on

material and printer choices. I use a Zortrax M200 printer

and have produced the components using the Z-Ultrax

material.

Base:

The base frame provides the support structure

for the elevator axis drive motor and belt transmission, and

the linear guides on which the upper moving carriage slides. It

also provides the mechanical end stops for the elevator

movement.

The design uses linear guides

with roller ball carriages rather than the round rails with

linear bearings used in the original yoke.

|

Carriage - slides on the base frame guides and

carries the aileron axis drive. |

The elevator drive is the same as for the

original yoke - a 3mm pitch toothed belt driven by the

brushless motor at the rear and with an idler pulley at the

front. The idler pulley is supported in a 3D printed housing

which can be position adjusted to provide belt tensioning.

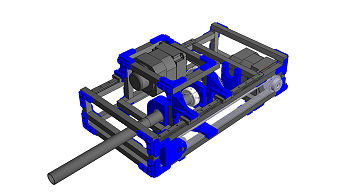

Carriage:

The moving carriage sits on the linear guide

rails on the Base to provide the elevator axis movement. It

carries the Aileron axis drive motor and single belt stage

which rotates the yoke tube. The yoke tube is supported in

needle roller bearings housed in 3D printed bearing

housings. The front bearing housing also provides the

aileron axis mechanical end stops.

|

DIY CL Yoke - constructed from OpenBeam beams

and 3D printed parts |

Care needs to be taken on assembly of the Carriage on the

linear guides - the guide rail fixing screws should be left

loose during assembly to ensure that the rails find their

true parallel positions when the carriage is mounted. They

are then tightened once the carriage is secured and so allow

smooth fore/aft movement for the elevator axis.

The resulting movements in both the elevator and aileron

axis are very smooth, and the loading from the brushless

drive motors and BFF CL cards is as smooth as expected

from the BFF CL system.

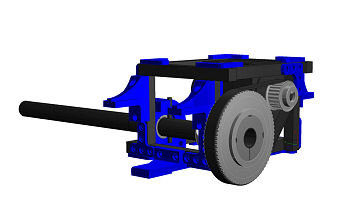

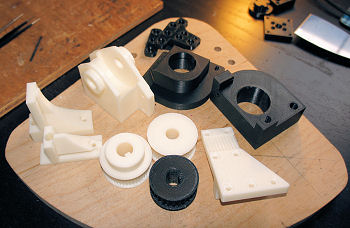

3D Printed Components:

|

3D Printed parts - including belt pulleys and

bearing housings |

Most of the components in the build aside from the OpenBeam

aluminium beams and bought transmission components

(bearings, belts) are 3D printed. The printed parts are:

-

L and T brackets to secure the beam sections together

-

Mounting feet

-

Yoke tube bearing housings

-

Linear rail fixing brackets (to secure the main carriage

to the linear guides)

-

Elevator axis belt attachment bracket (to connect the

belt to the moving carriage)

-

Drive and idler toothed belt pulleys

-

Idler pulley housing

-

Rear end stop for carriage

The quality of the 3D printing needs to be good for several

of the components. The bearing housings need dimensionally

accurate holes to accept and hold the bearings and the

toothed belt pulleys need accuracy to reproduce the tooth

forms fully and to produce the shaft mounting holes to the

required fit.

I use a Zortrax M200 printer and have used their

Z-Ultrax

material to good effect. I have found that some shrinkage

allowance on holes is required to ensure accuracy for

bearing and shaft fits. On the belt pulley shaft holes about

0.15mm oversize allowance is needed to end with a firm press

fit of the pulley onto the motor shaft. On the larger

bearing housings about 0.2mm allowance is required.

One particular advantage with the belt pulleys is that an

integral key can be included in the printed pulley shaft

hole which makes fitting the pulley much more

straightforward than before.

There's a fair bit of printing time involved, but if you

have access to a 3D printer it should still work out fairly

inexpensive in terms of filament cost.

Movie Clips:

Here's a YouTube clip of the yoke....

Drawings and Specifications:

UPDATE Nov '18

To use 60ST-M01330 servo motors in the yoke,

flange adaptors and a few other parts are required.

60ST Motor

Adaptors STL Files

NOTE: To use the 60ST motor, the drive

belt on the aileron axis must also be changed from the

450-5M-15 shown in the buy-list to the shorter 425-5M-15.

The adaptor places the motor centreline slightly closer to

the yoke tube and so a shorter belt is required.

UPDATE 13/1/17

I've updated the yoke plans pdf - it now

includes the build sequence and more details of the

components. Click on the image for the pdf.

I hope also to be able to offer the full set

of 3D printed parts for sale.

UPDATE 18/1/17 Buy List and .stl files

for 3DP printed components now available, see links below -

Buy_List.pdf

3D Printing

STL files

IMPORTANT: To work well the 3D

printed parts must be of good quality (dimensionally

accurate and with reasonable strength). This implies a

reasonably dense fill and good internal bonding. The belt

pulleys and bearing housings especially need good

dimensional accuracy on internal diameters used for shaft or

bearing location. You may need to experiment with these to

determine what if any adjustments are needed with your

printer and material to get internal hole diameters to give

a firm press fit of the pulleys on motor shafts, and of

bearing into housings.

For reference on the pulleys I increase the

hole diameter by 0.18mm on my Zortrax to get a good press

fit of the pulley on the motor shaft. The bearing housing

stl models already have a 0.15mm increase in dia on the

bearing housing holes to get a firm press fit of the bearing

into the housing.

I hope also to be able to offer the full set

of 3D printed parts for sale soon. Please contact me for

more information if you would like a set....

So more to follow - I'll add further details as

I get them ready....

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at