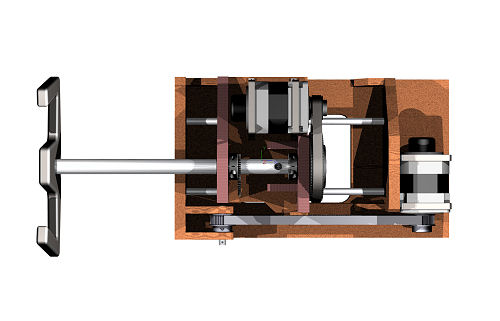

The yoke construction is fairly simple in

principal - but needs to be built accurately. The aileron drive motor, wheel tube and control

wheel (not included) are mounted on a travelling carriage, which itself is

mounted on low friction linear guides and linear ball bushings. The

control wheel tube is mounted in needle roller bearings on

the carriage. The

carriage is driven by the elevator motor via a toothed belt

loop. The elevator motor is mounted on the base structure of

the yoke at the rear.

Each movement axis is loaded by a

single 3 phase BLDC motor (fitted with 360 cpr quadrature

encoder). The motors are specified in the drawings. An

important characteristic is their sinusoidal

back EMF which enables

very smooth response to the sinusoidal commutation voltages from

the purpose designed BFF BLDRV3 drivers.

|

BLDC motors - used

with specialised controllers.. |

The BLDC motors are sized

to allow simple toothed belt torque

transmissions to be used whilst still providing good levels of force

output. These belt drives are easier to build than spur

gearing and are fairly tolerant of slight misalignments and

positioning errors likely to be found in DIY constructions.

The force levels are such that

at the higher levels

one handed

operation of the yoke becomes quite uncomfortable quite

quickly if the control is displaced or untrimmed. The yoke needs to be

secured to a fixed base otherwise it

will move under the generated loading. At full load with 24V

supply the elevator loading is about 9 kgf (20 lbs), one

handed aileron operation at full load requires about 4.25 kgf

(9 lbs). These forces are typically with the controls fully

displaced during a flight manoeuvre, force levels during normal flying conditions are

much lower than this off course.

Provision is made for fitting potentiometers to report

the control position.

NOTE the plans do NOT include details of the

control wheel - builders must source their own. The hollow

yoke tube shown in the design is 25mm outside diameter.

Wiring for any buttons on the wheel can be routed through

the yoke tube.

A number of videos clips of the prototype in operation are on

Page 2.

MOVIE CLIPS ON PAGE 2

Drawing Set Revision History

29/9/11 - Sheet S001-2 raised to R2 - corrected item 2

(front plate) width.

19/9/11 - Sheet A004-1 raised to R2 - corrected item 24

(belt) length.

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at