UPDATE Oct 2011 - The Mini Motion

Platform plans are now also available as part of the

Full Download Plans Set

available from the plans order page.

UPDATE 13th Feb 09 - Detailed

plans are now available for the Mini Motion Platform. They

are bundled FREE with orders for the

V2 Motion Driver software.

I think this mini-motion platform is probably my

favourite of the three I've built so far. The design draws on lessons

learned from the previous two builds and with it I've tried to

strike a balance between having enough motion to add real

enhancement to the sim experience whilst keeping the structural

complexity of the machine as low as possible. Keeping things

simple keeps the build cost down, makes it easier to build and

easier to maintain.

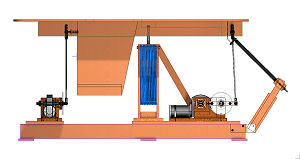

The platform is a 3 degree-of-freedom

small-displacement machine, it is a single seater and is small

enough to fit in the corner of my room. It is based on a fairly

conventional 3-point support type rig with a central sprung

support and stabilising column.

I thought quite hard about the motion range needed

for the platform to still make it worth building and it has +/-

9° pitch, +/- 13° roll and about +/- 85mm heave. These are a

good deal less than the movement capacities of the other

platforms on the site however when used with a visually enclosed

cockpit I believe they are sufficient to add a real sense of

motion to the flight sim, but to do it at as low a cost as

possible.

The platform is driven by 3 x 200W electric motors

each through worm gearing and a single roller chain reduction

stage. The final drive sprockets carry the crank arms to which

the three drive rods are attached and so rotation of the cranks

drives the pitch, roll and heave movement of the platform. The

majority of the platform weight is carried by the central

plunger type bungee cord spring. The spring column and the rear

mounted partial Sarrus linkage constrain horizontal linear

movement and yaw rotation of the platform. The majority of the

construction is in timber and the more heavily loaded machine

elements are in steel. Rolling element bearings are used in the

drives and linear ball bushings are used to constrain and guide

the motion of the bungee plunger spring. I've stiffened up the

structure in places as a result of seeing the prototype

machine's behaviour.

Here's a short movie clip of the prototype

running .... Platform 3 Clip,

(note that the CAD design shown has a bigger

motion range than this prototype platform,

there is the odd squeak and click due to lack of

lubrication in places)

The platform is driven using the motion drive

software and single chip SPU servo hardware described on the

site. I have used a 36V battery supply to drive the nominally

24V drive motors to generate better speed and load capability -

even with this the MD03 speed controllers and the drive motors

show little signs of heating in use indicating low current

draws. I think the drive gearing has given the drives good force

capability which is a good sign for when I want to add a heavier

cockpit.

IMPORTANT NOTE - the Chinese made 200 W electric

motors I used in the build have become difficult to source. You

will probably have to find alternative motors if you wish to

build a similar platform, if so some speed and torque figures

for the actuator crank arm might help - on my platform the

torque at the crank arm is 42 Nm at the motor rated torque

output and the max speed of the crank arm is 68 rpm.

Above are a couple of photos of the prototype

build. I fitted a simple fabric covered hood as a temporary test

arrangement to enclose the

cockpit and used a projector to display the main front view from

over the pilot's head. An LCD display is used to display the

instrument panel. I think the performance of the platform is

surprisingly good. The heave movement is sufficient to provide

touchdown-bump effects, take-off motion, turbulence motion and

general in-flight heave effects. The pitch motion is sufficient

(with well tuned software setup) to allow me to feel

acceleration and braking forces both on the ground and in the

air and to induce a sense of pitch rotation, and the roll motion

is good for roll rotations and lateral acceleration force cues.

The rig will not have you "hanging in your harness" on heavy

decelerations but for GA type flying I like it as it appeals to

my preference for simming with as much realism as possible in

the flight conditions.

I haven't tried tuning the motion for fast jets yet

- I'll get round to it and see what it feels like.

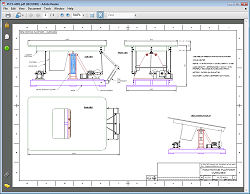

PLANS

Detailed plans are available for the Mini Motion

Platform. They are bundled FREE with orders for the V2

Motion Driver software,

AND they are now also included in the

Full Download Plans Set

available from the plans order page.

The plans consist of 13 A3 sheets covering the

detailed mechanical parts and assemblies of the platform. For

the control system hardware and software see the relevant web

pages.

I've added a few more CAD renderings of the design

below - click on an image to get a bigger view.

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at