UPDATE

Jan '08, I've made available a series of high-resolution

CAD images of the main assemblies

of the motion cockpit for any other DIY'ers who are interested in

the construction principals - you can see them

here.

UPDATE

Jan '08, I've made available a series of high-resolution

CAD images of the main assemblies

of the motion cockpit for any other DIY'ers who are interested in

the construction principals - you can see them

here.

For the FSX/FS2004 driven flight sim motion cockpit

I've gone for a three degree of freedom system – two rotational DOF's to simulate the forwards/reverse (fore/aft) forces and the

sideways (lateral) forces acting on the pilot, and a linear vertical

or heave DOF to try to deal with some of the vertical force effects. The fore/aft

forces arise mainly from changes to the aircraft's forward speed

(velocity) such as on take-off and landing, but also as a result of

the pitch attitude of the aircraft. Testing has suggested that lateral forces

during turns are generally light and mainly arise

from slippage effects but the roll motion is important in developing

a feeling of roll so there is a contribution

from the roll angle of the aircraft, and the vertical forces arise

from the heave movements of the aircraft in flight and also from

discrete events such as touch-down bumps on landing or running off

the end of runways (I know, I should practice more).

For the FSX/FS2004 driven flight sim motion cockpit

I've gone for a three degree of freedom system – two rotational DOF's to simulate the forwards/reverse (fore/aft) forces and the

sideways (lateral) forces acting on the pilot, and a linear vertical

or heave DOF to try to deal with some of the vertical force effects. The fore/aft

forces arise mainly from changes to the aircraft's forward speed

(velocity) such as on take-off and landing, but also as a result of

the pitch attitude of the aircraft. Testing has suggested that lateral forces

during turns are generally light and mainly arise

from slippage effects but the roll motion is important in developing

a feeling of roll so there is a contribution

from the roll angle of the aircraft, and the vertical forces arise

from the heave movements of the aircraft in flight and also from

discrete events such as touch-down bumps on landing or running off

the end of runways (I know, I should practice more).

Testing of the system has brought

up some surprises for me in which of these DOF's is the most active

under different flight conditions – mainly heave with not much in

the way of sideways accelerations.

|

Support Frame

|

The working principal is to try to

simulate the force effects on the pilot - not to simulate the

apparent

aircraft movements. Shown in a lower image the

flight sim motion cockpit is covered with a light-weight hood and when in

flight the pilot has no visual

signals of the external movements of the simulator – all he/she sees is the view of FS2004 on the computer screen and at the same time feel

forces that match what's happening in the virtual world

he's flying in. For a more lucid

explanation of this check out ForceDynamics' "how it works page"

here (and

while you're there watch their videos - that's performance that will

be hard to match).

Looking at the CAD images you'll see

I've gone for a one-sided or cantilevered design for the flight sim motion

cockpit.

This is quite a bit different from most of the movement platforms

I've seen. It does introduce some

structural

challenges but it leaves one side completely open for pilot access and

reduces the overall footprint of the equipment. It is installed up against a solid wall which provides

much of the load support for the structure. The cantilevered

design also makes the heave DOF drive design relatively simple and

allows important counter balance weights to be incorporated into the

arrangement with out too much difficulty – all of which are

positioned away from the side where the users would congregate. The

arrangement also allows fairly generous movement ranges to be

designed-in which directly affect the range of flight conditions

that can be simulated – these are detailed below. Testing has shown

that I don't need all of the pitch and roll movement available,

although it does look like the more heave stroke there is the better.

The question of weight balance in the

system is important because it directly affects the power required

to drive the cockpit movements, and for a

given

set of drive motors it affects the response times they are able to

induce in the simulator. The lower the drive power required the

smaller the motors need to be and the cheaper the cockpit build will be -

power capacity affects most of the elements in the mechanical and

electrical power transmissions.

The rotational DOFs are brought into

balance by trying to ensure as much as possible that the axes of

rotation of the pitch and roll movements pass through the centers of

mass of the moving cockpit and pilot. This geometry is built

into the design and some minor adjustment should be possible by

slightly altering the seating position of the pilot. However the

heave DOF can only really be brought properly into balance by adding

counter weights, my provisional plan here was to use a number of

15kgf batteries for this because they are heavy, compact and I've

got several old ones sitting about. In the end I used a combination

of batteries and bungee or shock cord springs which reduces the

added mass in the system.

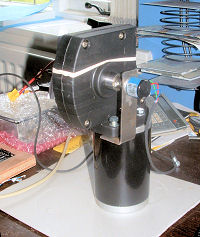

I have used four inexpensive

24V 200W DC PM motors to drive the movements. Two motors drive

the heave DOF which requires the most power, and one each

for the rotational DOF's.

Each motor is fitted with a worm gearhead which limits

to an extent the ability of the simulator to back drive through the motor and

helps the simulator hold position better without drawing much

power. It's important to say that the 200W rating of the motors is

their continuous use rating. Like most DC PM motors they are capable

of short term outputs much higher than this. It's modest commercial

aircraft levels of performance that the design is aimed at and it

looks as if it will be the heave DOF that will be most affected by

any power limitations there are.

I did the inertia and

acceleration sums and was interested to see what

the performance actually turned out to be. Generally the

power consumption is less than I anticipated. Only the heave

movement motors and controllers show any signs of warming

(indication of current draw) and the 20Amp speed controller driving

both heave motors stays well within its normal temperature range. I

suspect that less than 200W is needed for the two rotational DOF's.

Mechanical power

transmission is by roller chain drives which are quiet,

stiff, non-slip and relatively tolerant of misalignments

between the moving parts, they are also relatively

inexpensive to build. One unanticipated effect of the chain

drive on the heave movement was the transmission of chain on

sprocket vibration through to the cockpit at the higher

heave speeds. In the end I made

up and added a mechanical vibration isolation unit which

removed this vibration transmission - I have found that anything you can do to

smooth the movement improves the simulation effect.

Some technical details -

Heave displacement - +/- 200mm

(more if the structure height is increased, an advantage of using

counterbalance weights is that the heave DOF remains in balance over

the full stroke length). If I was to build it again I would add more

heave stroke length to give more scope for acceleration development.

|

|

Support Frame

with Heave Cradle assembled

|

|

With Cockpit and

Screen Added - scope is there for a more realistic cockpit

fit-out.

|

|

Motionulated Forward Acceleration

- it became clear during testing that the full angle wasn't

needed to deliver strong force cues and the rig is now

limited to about +/- 30 Deg Pitch.

|

|

|

Pitch - +/- 60 Degrees – the

pilot needs to be strapped in! Theoretically a 60 Deg pitch

backwards of the simulator simulates a forward acceleration of

nearly 0.9g . On testing it became apparent that to deliver

impressive force cues as much as +/- 60 Deg isn't needed. The normal

working range of the rig is now

limited to +/- 30 Deg, which also reduces the operating stresses on

the kit.

Pitch - +/- 60 Degrees – the

pilot needs to be strapped in! Theoretically a 60 Deg pitch

backwards of the simulator simulates a forward acceleration of

nearly 0.9g . On testing it became apparent that to deliver

impressive force cues as much as +/- 60 Deg isn't needed. The normal

working range of the rig is now

limited to +/- 30 Deg, which also reduces the operating stresses on

the kit.

Roll - +/- 40 Deg – enough to

simulate lateral accelerations of about 0.6g, again a fairly

respectable level. Again on testing it was clear that this capacity

was likely to be unused. In reality there is little lateral forcing

felt in a banked aircraft - especially if the turns are coordinated.

What does seem to matter in the simulator is cueing roll rate - ie

delivering a sensation of rolling that matches the on-screen

visuals. This can be done by rolling in the right direction but at a

lower rate and then slowly washing-out back to zero at a rate unnoticed by

the pilot. If large roll angles are maintained in the cockpit the

sustained sideways forcing felt by the pilot is not realistic. Where

this might be different is during ground manoeuvres - turns on the

ground do produce sustained lateral forcing.

However, it turned out that the

un-needed angle capability was in fact needed - but to provide a

runoff movement following triggering of the cockpit's limit

switches. It takes a moment for the movement to slow to a stop even

when the power is cut to the drive and the extra rotation allows

this deceleration to happen before the actual physical end stops are

hit. It was wise to design the capacity in - I just didn't use it

the way I'd intended.

(For interested readers the human model

shown in the CAD design is derived from body shells made

available by

M P Reed at the University

of Michigan. They are based on anthropometric data for crash

test dummies, data which also contains very useful mass and

inertia data - see his downloads page.)

The CAD images on the page show the

flight simulator motion cockpit in a range of operating positions –

the light-weight cockpit hood fitted on the built design but not

shown in the CAD images is very important for developing the

full effect of the simulation.

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at