|

3-DOF

Motion Cockpit - initial design. |

JAN '08 I've had a number of enquiries about detailed

mechanical plans for the motion cockpit, or for details of

the construction. I don't intend to draft a full set of

detailed plans as I think the design is probably a bit too

complicated for many DIY'ers (not all) and the returns won't

justify the outlay in time to prepare the plans.

However

to provide some help for other DIY'ers I've tidied up my 3D

CAD model of the design and made one or two changes to

reflect mods made during and after the build and have

produced a series of high resolution images which should

show, at least, the principals of the construction.

Not all fasteners have been included in the images.

I've added one or two comments where they might be

helpful - but this page is really just about the images.

Note you can't get accurate dimensional information from the

images - for that type of detail you would need the 3D CAD

model and the CAD software to read it.

NOTE - some of the

images are quite large and may take a moment to download.

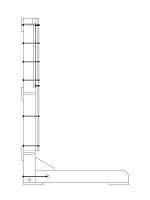

Motion Cockpit Wall Brace

Timber structure but with steel flats for roller running surfaces

- the rollers are heavily loaded.

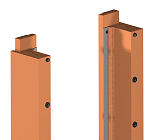

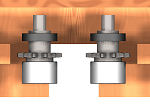

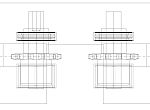

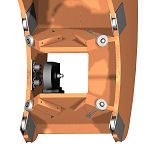

Heave Carriage

Timber with steel stress components. The motor drives a 3/8"

roller chain to pitch the cockpit cradle (see below). Needle

roller bearings and thrust ball bearings on the main cradle

support pin. The lower-most rollers should be soft-tyred (eg

roller blade wheels) for quiet rolling on the cradle. I

eventually fitted a small vibration isolation connection where

the support chain is attached to remove slight but noticeable

chain vibration from the cockpit.

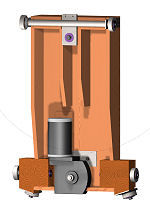

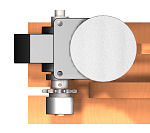

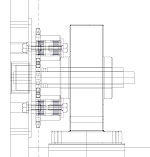

Heave Drive

Mounted at the top of the wall brace, again 3/8" pitch simplex

roller chain (might be better with duplex chain) carries the

cockpit and is driven by the 2x200W motors. The heave feedback

potentiometer is mounted on one of the idler sprocket spindles.

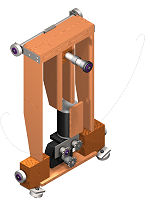

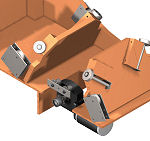

Cockpit Cradle

Key elements are the angles rollers which prevent fore-aft

movement of the cockpit - these are heavily loaded when in use

and need to be rigidly supported.

3/8" pitch simplex roller chain to drive the cockpit roll

movements.

Cockpit

Light-weight timber structure. Key part is the curved running

surface for the fore-aft movement constraining rollers on the

cradle. I used Ø12mm steel reinforced electrical power cable for

this (shown in black) bonded to the curved plywood formers.

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at