|

Comms Speed

Enhanced SPU |

Summer 09 - A ready built higher

speed Signal Processor card is now available to buy -

this does away with all the breadboard electronics and

fiddly wiring - see the 40SPU-1 card

page for up-to-date details.

April 09 - I've completed work on a

High-Speed SPU based on

the newly released PICAXE 28X2 chip - faster response and

smoother control.

February 09 - Added real-time speed controller condition

monitoring to allow you to keep an eye on your drive system

loading.

January 09 - With the prototype Mini-Motion Platform

(Platform 3) now built and running I've had time to take a

look at some improvements to the control system.

I've already described my experience with the

use of US Digital's MA3 position encoders on the

MA3 Encoder page.

These improved the position feedback signals

available to the Signal Processor Unit by reducing the noise

levels on the signals. A further improvement that can be

made is to increase the data transfer speeds between the SPU

and the PID Servo Controller software running on the driving

PC.

The serial communications between

the PICAXE 28X1 chip and the PC using the basic SPU run at 9600 baud. This is

the speed limit of the serin/serout commands on the 28X1

when it runs with its internal 8MHz clock speed. The 28X1

however has "hardware" serial comms capabilities which are

capable of running at 115200 baud. The much faster comms

speed has the effect of minimising the small delay that

occurs between the sampling of the instantaneous position of the platform by the SPU and a correcting set of motor speed

demands being received by the motor speed controllers. The

time delays here are very small but they are significant in

affecting the smoothness of the drive as felt by the pilot

in the motion platform. The delay is reduced because the

time taken to send and receive data is reduced at the higher

baud.

|

RS232 to TTL

Converter Module |

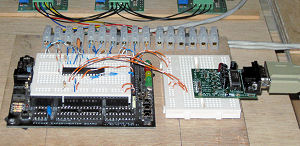

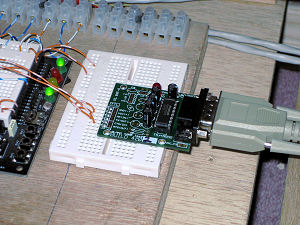

Implementation of the 115200 baud serial

comms requires an additional bit of signal processing

hardware on the SPU. This is because the "hardware" serial-in pin on the 28X1 chip requires true RS232 voltage

polarities at TTL (5V) levels. For serial comms with a PC

this needs either a RS232/TTL Converter Module or a separate

MAX232 converter chip to be incorporated into the data line.

Either approach will work although I've chosen to use

an RS232/TTL

Converter as this is neater for me and also allows a

standard serial cable to be plugged in directly without

having to strip wires etc. The converter module I used has

its TTL connector pins physically inverted and so can be

pressed directly into the breadboard which allows very

simple further connection to the 28X1 chip and the available

5V board supply - see image above.

I've recently come across this

AVITResearch

USB to TTL converter

cable. This has the MAX232 type level shifter circuitry

built into it and can be connected directly to the serial

read and write pins on the PICAXE chip. More expensive than

a MAX232 chip and some capacitors but much less hassle. If

you do use it connect cable blue to 28X1 pin17 (Position

Out) and red to pin 18 (Speed In).

RESULTS

Combined with the MA3 Encoder position

feedback and V2.02 driver and PID software running on a LAN

PC I've found the 115200 baud SPU does improve the quality

of the Mini Motion Platform motion. On my LAN PC I get

refresh times on the PID Servo Controller of around 0.03s

(33 loops/s - see performance tips below) and a smoother

drive. There now seems more scope for adjustment of the PID

control terms and in particular both the Proportional gain

and Derivative term can be strengthened to improve the

higher frequency response for on-ground operations. This

improves touch-down bumps and runway rumble effects.

Generally the in-air motion also seems smoother.

Overall I think it is a worthwhile

enhancement and when the PICAXE 28X2 chip becomes available

the full resolution of the MA3 feedback encoders can be

realised to take the picaxe based SPU to the probable limit

of its capabilities. - UPDATE April '09 - the 28X2

chips have now been released and I've completed work on a

High-Speed

SPU - click on the link.

SPEED CONTROLLER CONDITION MONITORING

The

faster communication speeds available with this enhancement

can be used to add additional capabilities to the system.

One very useful addition is to read real-time current and

temperature data from the MD03 speed controllers and to send

this back to the PID Servo Controller software for display.

This allows you to keep an eye on the real-time loading on

the MD03 speed controllers. You can confirm how heavily

loaded they are generally and can watch out for potentially

damaging current flow or controller temperature rise. This

will be particularly useful during the initial motion

platform setup and commissioning activities when the

patterns of the controller loading might not yet be known.

The

faster communication speeds available with this enhancement

can be used to add additional capabilities to the system.

One very useful addition is to read real-time current and

temperature data from the MD03 speed controllers and to send

this back to the PID Servo Controller software for display.

This allows you to keep an eye on the real-time loading on

the MD03 speed controllers. You can confirm how heavily

loaded they are generally and can watch out for potentially

damaging current flow or controller temperature rise. This

will be particularly useful during the initial motion

platform setup and commissioning activities when the

patterns of the controller loading might not yet be known.

I've put together some additional wiring

diagrams etc for the Enhanced SPU set up and there are also

new chip flash programs to handle the faster serial

communications (I've included a .bas program which adds the

115200 serial comms to the existing SPU without the MA3

encoders - a 16MHz resonator will still be needed).

|

28X1 Pin Designations

(with MA3

Encoders) |

Enhanced SPU Wiring

(with MA3

Encoders) |

Enhanced SPU

System Wiring |

Enhanced SPU

.bas

Flash Progs

Three versions

are

included - for

normal

potentiometer

feed-

back and for

MA3

encoder

feedback and

a version for

speed

controller

monitoring. |

Note the SPU is built on the

PICAXE Experimenter Kit breadboard (this kit has been

discontinued by PICAXE -

this is the replacement). If you use the AVITResearch

USB to TTL converter

cable then connect cable blue to 28X1 pin17 (Position

Out) and red to pin 18 (Speed In).

PERFORMANCE TIPS

To get the best performance out of this

low-cost drive system there are a few recommendations

worth considering.

-

If possible run the V2 Motion Driver

and SPU Servo Controller on a LAN PC separate from

the main flight sim PC. This will reduce the demand

on the main PC and also give the best fresh speeds from

the motion software. The V2 software is more CPU

demanding and is likely to run faster when not

fighting the flight sim for CPU time.

-

On the LAN PC try setting the process

priority of the Motion Driver slightly lower

than the PID Servo Controller (for example at

BelowNormal) - be very careful however and stand by

the emergency stop button! On my set up the

controller remains stable and runs at a consistently

faster refresh speed, however this may not be the

case on all systems and it will also depend on

the overall demand on the LAN PC - be careful if you

try this.

-

If you do not want the Articulated

Projector drive output from the V2 Motion Driver set

the output mode to NONE in the vis.cfg configuration

file (in the line near the bottom of the file -

change "Pololu" to "NONE"). This will reduce the CPU

demand.

-

Use the Enhanced SPU hardware with

the US Digital MA3 position encoders - this will

improve the quality of the motor control and give

more flexibility in your PID configuration. For the

PID Servo Controller to run at 115200 baud the

PID2.cfg file must be modified - line 28 should be

changed from "9600" to "115200" to set the correct

baud. If you find that line 28 is blank in your

PID2.cfg file then add a new line with "115200"

(without the inverted commas).

-

Move the main supply voltage for the

MD03 motor speed controllers up to 36V - ie use 3 x

12V batteries in series rather than 2. Although the

motors I use are nominally rated at 24V increasing

the voltage supply to 36V has no detrimental effect

on them in my set up. The higher voltage increases

the torque available when the motors are

accelerating or decelerating. Given the short

actuator stroke length it is not likely that the

motors will over-speed, it is the added current flow

and so higher torques that are of interest. If you

try this be sure to monitor carefully the working

temperatures of the motors and the speed controllers

for signs of overheating - a sign of excessive

current flow.

Overall the aim is drive smoothness and I

think the speed enhanced SPU takes us a further step in

the right direction. My

experience is that if the motor drive is slightly rough

then it does not feel right to the pilot in the motion

platform. When some roughness is expected - for example

when on the runway then that's okay but for normal

flight motion you want the platform motion to be a

smooth as you can possibly get it.

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at