IMPORTANT - Ready-Built motion platform drive hardware is now available to buy -

this does away with all the breadboard electronics and

fiddly wiring - see the 64SPU-1 card

page for more details.

April 09 - I've completed work on a

High-Speed SPU based on

the newly released PICAXE 28X2 chip - faster response and

smoother control.

With the motion platforms operational for a while

now I've been able to think through and implement some substantial

improvements and simplifications to the platform control

system. Any way in which the build process can be made

easier and less expensive will make life a bit easier for DIY'ers, and the electrical and control system is a major

part of this. The control hardware has evolved through a

number of variations and is now quite simple and fairly

easily built by competent DIY'ers.

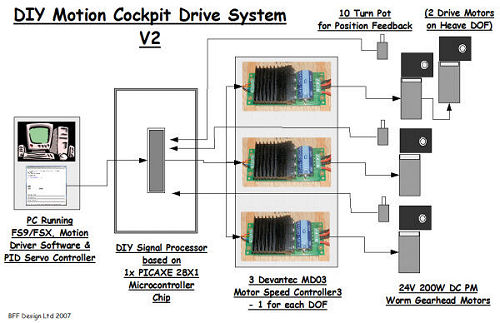

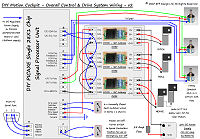

The basic control system is shown above. The

BFF Motion Drive software runs on the sim PC or over a LAN

and generates the platform motion cues. These are shared

with the PID Servo Controller software which runs on the

same PC as the motion driver. The PID Servo Controller

software runs 2-way serial communications with the external

DIY Signal Processor Unit (SPU). The SPU uses a single

PICAXE 28X1 chip to act as a communication device passing

platform position feedback information to the Servo

Controller software and sending calculated motor speed and

direction instructions on to the MD03 motor speed

controllers which in turn drive the electric motors.

The SPU drives the MD03 speed

controllers using the PICAXE chip's

built-in

Philips I2C

capabilities with the single

PICAXE 28X1 chip

as the I2C bus master.

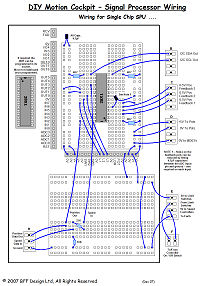

Single Chip Signal

Processor Unit (SPU)

The SPU uses only a single 28X1 PICAXE

chip. Its role is to collect and write

the platform position feedback information to the PC, and

then to

read back speed demand information and pass it straight

through to the motor speed controllers. It does have

further important jobs - one is the critical role

of detecting loss of signal from the PC. It detects time-outs on the serial data read which allows the SPU to

react almost instantly to any loss of the speed demand

instructions from the PC and to stop the drive to the

platform before any damage is done should the PC or any of

the software hang.

The SPU uses only a single 28X1 PICAXE

chip. Its role is to collect and write

the platform position feedback information to the PC, and

then to

read back speed demand information and pass it straight

through to the motor speed controllers. It does have

further important jobs - one is the critical role

of detecting loss of signal from the PC. It detects time-outs on the serial data read which allows the SPU to

react almost instantly to any loss of the speed demand

instructions from the PC and to stop the drive to the

platform before any damage is done should the PC or any of

the software hang.

The position feedback send

and speed demand read are done on the same Serial line to

the PC (and with the correct download cable from PICAXE can

be driven from a USB port instead so only a single Serial

or USB port is needed - important, see

note at page bottom). The comms in the basic SPU is at 9600 Baud and is fast

enough to allow overall data refresh rates of 25 sets/sec or

higher. The Enhanced Speed SPU

comms run at 115200 baud which has a significant effect on

the control quality.

The position feedback send

and speed demand read are done on the same Serial line to

the PC (and with the correct download cable from PICAXE can

be driven from a USB port instead so only a single Serial

or USB port is needed - important, see

note at page bottom). The comms in the basic SPU is at 9600 Baud and is fast

enough to allow overall data refresh rates of 25 sets/sec or

higher. The Enhanced Speed SPU

comms run at 115200 baud which has a significant effect on

the control quality.

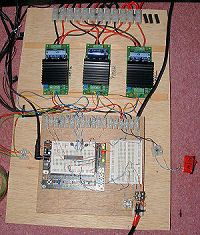

The communication with the speed controllers

makes use of the built-in I2C functions of the

PICAXE chip and of the

MD03 controllers - the wiring is

simple as each controller is linked to the

same two SCL and SDA lines from the SPU - the mode switches

on the MD03's are simply adjusted to give each a separate

"address" on the I2C bus.

There are a number of variations on the

Signal Processor Unit design now available. These cover

different comms speeds and different types of position

feedback devices, they are-

-

BASIC SPU - Uses 28X1 Chip's 8MHz

internal clock, Potentiometer feedback devices and 9600

baud serial comms. Wiring details and diagrams are

below. Option available for 16MHz

clock speed.

-

BASIC SPU + Encoder Feedback - As above

but uses MA3 absolute position encoders for cleaner

position feedback and an external 16MHz clock

(resonator). Details on the

MA3 Encoder page.

-

ENHANCED SPEED SPU - Uses a small amount

of additional hardware to run serial comms at the much

higher 115200 baud. Also needs an external 16MHz

resonator - details on the

Enhanced SPU page.

-

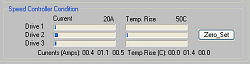

ENHANCED SPEED SPU + Speed Controller

Condition Monitoring - as for the ENHANCED SPU above but

adds real-time speed controller current and temperature

monitoring - requires V2.05 or later of the PID Servo

Controller software. Details on the

Enhanced SPU page.

-

FINALLY, if your don't want to try and

build your own SPU a ready-built signal processor unit

card is available to buy. The

40SPU-1 card uses the PICAXE 28X2 chip and runs at

40KHz - faster than the above options, and has several

additional features. For more details see the

40SPU-1 card page.

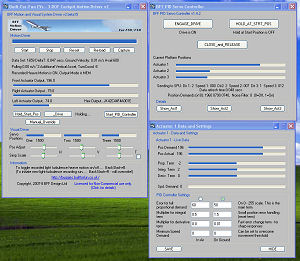

PID Servo

Controller Software

The control system is driven by the PID Servo Controller

software that runs on

the same PC as the BFF Motion Driver.

This is where the servo control calculations are done using

the position feedback information from the SPU and the

position demand information from the Motion Driver. As of

April 2009 V2.1 of the PID Servo Controller is available.

With

system safety in mind the servo controller runs as a separate process

on the PC and communicates with the Motion Driver through a

shared memory area - so any hangs or crashes in the flight sim or Motion Driver will not stop the Servo Controller from

continuing to send control data to the external hardware.

This gives the system two layers of failsafe - one at the

PICAXE chip level which monitors data output from the PC and

the other at the Servo Controller software level which

monitors data output from and the status of the Motion

Driver - both are programmed to cut the drive to the

platform should the data stop flowing.

With

system safety in mind the servo controller runs as a separate process

on the PC and communicates with the Motion Driver through a

shared memory area - so any hangs or crashes in the flight sim or Motion Driver will not stop the Servo Controller from

continuing to send control data to the external hardware.

This gives the system two layers of failsafe - one at the

PICAXE chip level which monitors data output from the PC and

the other at the Servo Controller software level which

monitors data output from and the status of the Motion

Driver - both are programmed to cut the drive to the

platform should the data stop flowing.

This failsafe protection is

necessary. The motor speed controllers act on signals which

request a certain platform speed - not position! The rest of

the control system has to figure out how fast and in what

direction the motors should be running at any moment. If the

control system fails and the speed demand instructions to

the controllers are not constantly updated then the platform

may simply continue to drive at the last requested speed -

straight into the end-stops. The double protection built

into the new design substantially reduces the chance of this

happening.

The BFF PID Servo Controller

is started from the Motion Driver. It uses standard PID control algorithms to determine the required platform

speed to try to get the actual movement to follow the motion described by the Motion

Driver. The settings used for each of the three drive

outputs can be set "live" as the platform is operational so

you can see immediately the effects of your adjustments

(care required). The

input and output motions can be compared visually, and you

can see the magnitude of the individual PID terms as they

change in real-time. You can also dump a data trace to file

from which all of the variables can be plotted if you wish

to examine your platform response in more detail.

The BFF PID Servo Controller

is started from the Motion Driver. It uses standard PID control algorithms to determine the required platform

speed to try to get the actual movement to follow the motion described by the Motion

Driver. The settings used for each of the three drive

outputs can be set "live" as the platform is operational so

you can see immediately the effects of your adjustments

(care required). The

input and output motions can be compared visually, and you

can see the magnitude of the individual PID terms as they

change in real-time. You can also dump a data trace to file

from which all of the variables can be plotted if you wish

to examine your platform response in more detail.

There is a good article about

PID control

here should you need more detail. In short the final

speed demand for each drive is made up from three elements -

-

the Proportional term is

the main element and sets the speed proportional to the

size of the position error.

-

the Integral term adjusts

the speed based on the accumulating error and is useful

for ensuring the pitch and roll angles return fully to

their upright positions.

-

the Derivative term

adjusts speed on the basis of how fast the error is

changing and can acts as a brake on the system to

reduce overshoot. It can also be used to increase the

controller reaction to sharper position demand changes. This term is the trickiest to work

with as it is most affected by noise in the feedback

signals which can make the response very jumpy. See the

US Digital Encoder support page for how this can be

improved.

The V2 PID Servo Controller allows two sets

of PID settings to be specified for each actuator drive -

one for in-air operations and one for on-ground. This allows

a sharper control response to be specified in the drive

system for runway operations (touchdown bumps, rumble

effects, "off-road"

excursions

etc) and softer responses for in-flight motions.

With the

Enhanced SPU the V2.05 software also provides

real-time motor speed controller condition feedback to allow

you to visually monitor the drive system condition.

excursions

etc) and softer responses for in-flight motions.

With the

Enhanced SPU the V2.05 software also provides

real-time motor speed controller condition feedback to allow

you to visually monitor the drive system condition.

For the pilot's benefit the

PID Servo Driver has large start, stop and hold buttons

which allow you to kill the drive quickly should you need

to, and the Tab key remains programmed as a Hot Key to kill

both the Motion Driver and Servo Controller with a single

key stroke should your platform turn into a bucking bronco!

Here's a clip of the software

and SPU in action driving 3 of the DIY linear actuators -

Movie Clip

Wiring Diagrams for

the Basic SPU

The Basic SPU wiring details are

available below. The PID Servo

Software is included with V1.5 and later of the BFF Motion

Driver. Details of its use and set up are in the updated

User Manual also included in the software download package. The

manual is also available by itself on the

downloads page. For details

of the Speed Enhanced SPU

design - see here.

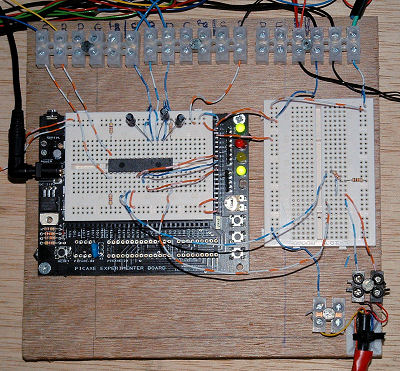

Below - Overall system

wiring, Basic SPU wiring and the 28X1 chip pin designations

.......Note the SPU is built on the

PICAXE Experimenter Kit

breadboard (this kit has been discontinued by PICAXE -

this is the replacement). The 28X1 chip flash program is included in

the motion driver download package.

Have fun ...................

Important Update

Information

If you are using older A.2 firmware PICAXE

28X1 chips then the serial communications require that a

calibfreq statement is included in the flash program to

calibrate the chip frequency. Make sure you are using the

correct .bas flash program (SPU_I2C.bas) and you may have to

experiment with the value used in the calibfreq statement.

If you wish to use the

AXE027 USB cable then I suggest that you alter the

"calibfreq -6" statement in

the flash program to "calibfreq -4" and give it a shot.

ABOVE APPLIES to A.2 Firmware chips only.

August 08 - IMPORTANT The

PICAXE 28X1 chip programming has been updated to allow

28X1 Firmware A.3 chips to be used. Use the SPU_I2C_16.bas program and have an external 16MHz

resonator fitted to the chip if you are using a A.3 firmware

chip. Or, you can use an A.3 28X1 with its internal 8 MHz

resonator if you use the SPU_I2C_8.bas flash program.

Original System Page

Original SPU Design

Original Controllers & Wiring

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at