NOTE This SPU has now

been substantially simplified to run with new PID Servo

Controller software - see here for

more details.

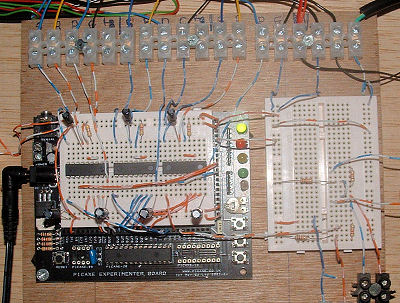

The OLD Signal Processor Unit is built around four programmable micro-controller

chips to process the digital cockpit position demand

data coming from the PC and to output matching speed demand

signals for the movement cockpit's motor speed controllers.

These micro-controller chips are amazing wee things, they only cost a few pounds

each and can be programmed to do all sorts of things. I have

used

PICAXE chips – one 28X

and three 18X, and have built up the unit around the

PICAXE

Experimenter Kit which provides a bread-boarding area for

your own component placement and solderless connections as

well as power supply connections, LEDs etc. (Check

here for

your local distributor of PICAXE chips.)

The

single 28X chip is the main data receiving chip and is located in the

connector provided on the Experimenter board. It reads the serial output

sent from the PC as

often as the PC can send it. It then splits the received data packet

into data for each DOF, tells the individual 18X chips that

new position data is ready and then, once it has their attention, sends the

position demand data on to the 18X chips.

The 18X chips are mounted on the white bread-boarding area

and each runs

one of the movement cockpit's DOF's. Each takes a position

demand from the 28X, reads the current DOF position from a

multi-turn potentiometer on its drive motor and determines

in what direction and how fast it needs to run the drive

motor to take the DOF to the new demanded position.

Each 18X

chips runs independently, continually monitoring the actual

position of the cockpit and adjusting its motor speed to

suit. Each will accept a new position demand from the PC

whenever one is available but without significantly

interrupting its control of the cockpit. This means that any loss

of signal from the PC simply results in the cockpit driving

to the last demanded position and stopping there.

28X, reads the current DOF position from a

multi-turn potentiometer on its drive motor and determines

in what direction and how fast it needs to run the drive

motor to take the DOF to the new demanded position.

Each 18X

chips runs independently, continually monitoring the actual

position of the cockpit and adjusting its motor speed to

suit. Each will accept a new position demand from the PC

whenever one is available but without significantly

interrupting its control of the cockpit. This means that any loss

of signal from the PC simply results in the cockpit driving

to the last demanded position and stopping there.

The calculation cycle in the

18X takes about 40ms, so each DOF has it's position

monitored and adjusted if necessary about 25 times per

second. The speed at which new position demand signals come

from the 28X however depends on how fast the Motion Driver

software running on the PC is exporting the data - and this

depends mainly on how fast it can be extracted from the FS9

simulation. With the current software version which uses

FSUIPC for all its data calls this is about once every

40ms also. The 18X chips only interrupt their position

monitoring/adjustment cycle when the 28X signals that new

data is ready - so not every monitoring loop involves a new

position demand input. For full details of how this is done

you can download the Flash programs for the chips from below

or from the downloads page - they are

written in a flavour of Basic and are fairly easy to read.

The main output from the

Signal Processor Unit to the motor speed

controllers is in the form of a 0 to 5V variable PWM voltage

(at 20kHz) which indicates required motor speed and a high/low 5V

signal to indicate forward or reverse drive. These are

compatible with the

Devantech MD03 H-Bridge motor

speed controllers used.

The main output from the

Signal Processor Unit to the motor speed

controllers is in the form of a 0 to 5V variable PWM voltage

(at 20kHz) which indicates required motor speed and a high/low 5V

signal to indicate forward or reverse drive. These are

compatible with the

Devantech MD03 H-Bridge motor

speed controllers used.

The Signal Processor has a few safety features built-in – for example

the 18X chip stops driving if the position feedback

potentiometer approaches its end of travel or produces an

end-of-scale reading, and the 28X chip shuts down if there

is a time-out on the data transfer hand-shaking with the 18X

chips. Note also that the cockpit is fitted with

end-of-travel limit switches which cut the logic supply

voltage to the MD03 motor controllers and so cut the drive

to the motors if any of the limit switches are triggered.

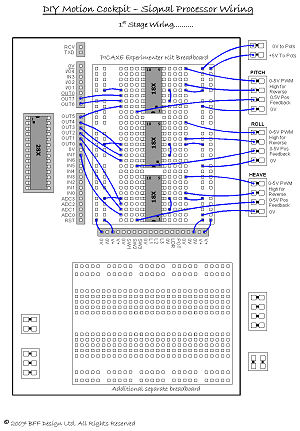

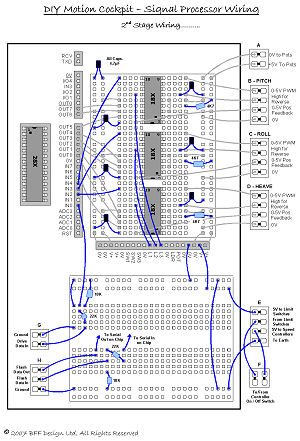

The PICAXE

micro-controller pin designations can be seen

here and

this can be read in conjunction with the flash programming

below to understand what's going on. The unit wiring is a

wee bit complicated and I've made up two wiring diagrams

which show the wiring tackled in two stages - the first

covers most of the core wiring on the Experimenter board and the

second shows the rest plus that on the second bread-boarding

area.

The Experimenter Kit comes

with a data sheet which shows how (after a bit of thought)

the base circuit board is put together - I think you can

also buy it pre-assembled. Once this is done

you can mount it and the second breadboard on a piece of

plywood and get on with the custom wiring. PICAXE

recommend that the low current logic type wiring on the

breadboards and chips is made with 1/0.6 mm single core

equipment wire. I used single 0.5 mm strand wire from

telephone cable with a small bend made in the stripped ends

to ensure a firm contact in the breadboard.

The capacitors in the system

are there as a protection from any voltage spikes in the pot

or reverse signal lines and are mainly a hangover from the

experiments with the 4QD Vortex speed controllers. I've left

them in as they don't seem to do any harm and will still

offer some protection. The resistors are as specified in the

standard PICAXE chip interfacing circuits and are necessary

so don't leave them out.

PICAXE Programming

The chip programming is in

Basic and is downloaded to the chips using the

PICAXE

programming software which is available free from their web

site. The local programming connections to the chips on the

board can be made using the "Read" and "Write" jump wires

which carry the signals from Connector H in the wiring

diagrams. Connect these to

the In and Out Serial programming pins on the chip you want

to flash. This can also be done by removing the chip from

the bread-boarding area and

installing it in the provided connector on the Experimenter

board, but this can be very disruptive once all the wing has

been made. Remember that the Serial-In pin must be tied low

when it is not connected to the programming circuit.

The original chip programs

were as

follows -

ReadPos.bas - the 28X flash

program - Read position data from PC COM

port & distribute.

Pos2SpeedPitch.bas - Pitch

DOF 18X program - Pitch motor

controller speed demand.

Pos2SpeedRoll.bas - Roll DOF

18X program - Roll motor

controller speed demand.

Pos2SpeedHeave.bas - Heave

DOF 18X program - Heave motor

controller speed demand.

The three 18X programs are

the same with the exception of some variation in variables

affecting speed and smoothness of response. The files can be opened using NotePad but are best

viewed with the free PICAXE programming software (they are

nicely colour formatted). I've

commented them fairly extensively so their function should

be understandable. They are available from the

downloads

page here.

As of October 07 there

are updated v2.0 chip programs available. These now have the

facility to be configured directly from the Driver Setup

program running on the PC - ie the key settings which define

the SPU performance for each DOF can be set from the PC

without the need to re-flash the chips. This greatly assists

the rig set up process and also simplifies the chip

programming process - each need only be flashed once and the

same program is used for all the 18X chips. The v2.0

programs are -

ReadPosGeneric.bas - the 28X flash

program - Read position data from PC COM

port & distribute + 18X initialisation and EEPROM

storage of settings.

Pos2SpeedGeneric.bas - A

single program to program all the 18X chips - motor

controller speed demand.

Both are available from the

downloads

page here.