UPDATE - This

page describes an early development of the servo control

system for the DIY motion platform. As of Summer 2009 a new

ready-built control card - the

40SPU-1, is available to buy which replaces all the

breadboard electronics. See the

40SPU-1 page for more up-to-date details.

The Signal

Processor and its

PICAXE chips work with low currents – nowhere near enough to

directly drive

the 200W DC motors used in the cockpit. This task is carried out in the system using bought speed

controllers. I've used several of these on the various

electric vehicle projects you can see on the rest of the

site and I thought initially I'd go with controllers I was

already familiar with for the movement cockpit prototype.

Specifically I looked at three of 4QD's 24V Vortex

controllers - a 35Amp unit for each rotational DOF

drive and a 75Amp unit for the heave drive. These did work

but were troublesome; they are of a type of speed controller

that uses internal relays to reverse the drive direction and

the switching of the relays caused a considerable amount of

electrical noise which caused instability in the Signal

Processor's micro-controller chips. This was largely solved

by adding capacitors and diodes to the connections between

the chips and speed controllers but still left a problem

with the speed and smoothness with which the drive motor

direction could be reversed. I also felt that the frequent

relay firing was starting to cause some mechanical problems

with the relays sticking which can have interesting results

- certain failures cause the controller to think it's

driving the motor in the direction opposite to its actual

motion!

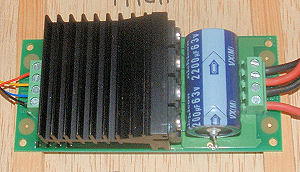

I

eventually changed the Vortex controllers out for smaller

Devantech MD03 H-Bridge controllers which implement their direction

reversals using solid-state switching and are much "quieter"

audibly and electrically. The latter makes life much easier for the chips.

Important also is that change of direction can be

accomplished without any delay arising from the

controller mechanical operation and this results

in much smoother movement at the cockpit. The experiment

with the Vortex units was very useful however as it also

gave me a much better feel for how much work the speed

controllers actually had to do - not as much as I'd first

thought. The MD03 controllers are only 20 Amp units and only

the one driving the paired Heave DOF drive motors shows any

sign of warming-up in operation.

I

eventually changed the Vortex controllers out for smaller

Devantech MD03 H-Bridge controllers which implement their direction

reversals using solid-state switching and are much "quieter"

audibly and electrically. The latter makes life much easier for the chips.

Important also is that change of direction can be

accomplished without any delay arising from the

controller mechanical operation and this results

in much smoother movement at the cockpit. The experiment

with the Vortex units was very useful however as it also

gave me a much better feel for how much work the speed

controllers actually had to do - not as much as I'd first

thought. The MD03 controllers are only 20 Amp units and only

the one driving the paired Heave DOF drive motors shows any

sign of warming-up in operation.

The MD03 units will accept a

range of control signals including the capability to follow

a 0 to 5V PWM speed demand signal and this is how they are

driven by the Signal Processor Unit. They seem effective at

holding the cockpit at any demanded position even when the

cockpit load is unbalanced - eg they are quite happy driving

the heave motion when the seat is unoccupied and there is a

significant unbalanced torque acting on the heave motors.

Putting the control system

together (The SPU design has now

been updated - click here)

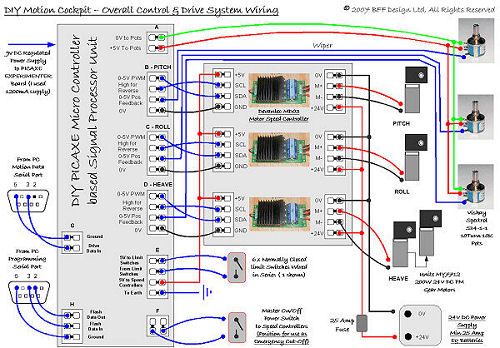

Below is a wiring diagram for

the overall system. This can be read in conjunction with the

wiring diagrams for the Signal Processor Units to understand

how the electrical system is put together. Click on the

image for a bigger printable version.

The Signal Processor Unit is

connected to the PC via two serial connections - one for the

chip programming and the other to receive the motion data. I

have both of these connected at once to different COM ports

to allow me to make changes to the PICAXE chip programming

when I need to. However if you weren't interested in

changing the chip programming the same COM port could be used for both

tasks - the

"Motion Data" connection could be made after the chips had

been flashed. You will have to cut up a couple of serial

cables to get the free wires to connect to the board - or

fit serial connectors directly.

The high current cabling for the electric motor

drive end is made with 2.5mm^2 35Amp cable which is

considerably thicker than the 1/0.6 mm single core equipment

wire recommended by PICAXE for the bread-board wiring.

The

multi-turn position feedback potentiometers are mounted on

their respective motor output shafts so that they signal the

actual position of the cockpit movement. It is very important that

they are wired so that the direction of increasing voltage output from the

pot matches the +ve direction of movement of the motor -

otherwise the position feedback loop will be unstable and

the cockpit will constantly drive into its end stops.

The

multi-turn position feedback potentiometers are mounted on

their respective motor output shafts so that they signal the

actual position of the cockpit movement. It is very important that

they are wired so that the direction of increasing voltage output from the

pot matches the +ve direction of movement of the motor -

otherwise the position feedback loop will be unstable and

the cockpit will constantly drive into its end stops.

The end-of-travel limit

switches should be positioned so that they are triggered and

held open as a DOF approaches its end of travel - best in

fact to set them some distance short of the actual physical end-of-travel

to allow some stopping distance for the drive. Often when

things go wrong (just when they are needed) the system will end up

driving towards the end stops with considerable speed and

some distance will be needed to decelerate the motion after

the power is cut. The

5V logic power supply to the MD03 motor controllers is wired

through the limit switches and the master on/off switch in

series - so any limit switch moving into an OPEN position

will cut the drive to all the motors. It is a good idea to

position the master on/off switch where it can be used as an

emergency cut-off switch by either the cockpit occupant or

an on-looker. Additional switches can be added in series as

needed.

A 9V DC regulated power

supply will be needed for the PICAXE Experimenter board, I

have used a 1200mA supply which doesn't seem to have any

difficulties with current capacity. The 5V supplies to the potentiometers and MD03

controllers are all taken from the Experimenter board. I am

currently using two very old 12V 38AmpH Lead-Acid deep cycle

batteries from previous electric vehicle projects to power

the drive motors but a mains powered 24V DC power supply

with a capacity of about 25 Amps might do - check the MD03

documentation or manufacturer for compatibility.

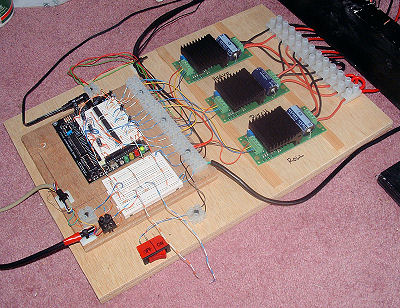

The main elements of the

system are mounted on plywood and secured to ensure they

don't move about, as are the cables which are secured with

cable ties. The breadboard cabling is susceptible to

loosening if other cables etc are dragged over it (eg as the

motion cockpit moves) so make sure the Signal Processor Unit

is protected with a cover. Try to keep the LEDs on the

Experimenter board visible though - they flash each time a

new position demand is processed and give a very useful visual

indication that the system is running and how fast it is

processing data.

The main elements of the

system are mounted on plywood and secured to ensure they

don't move about, as are the cables which are secured with

cable ties. The breadboard cabling is susceptible to

loosening if other cables etc are dragged over it (eg as the

motion cockpit moves) so make sure the Signal Processor Unit

is protected with a cover. Try to keep the LEDs on the

Experimenter board visible though - they flash each time a

new position demand is processed and give a very useful visual

indication that the system is running and how fast it is

processing data.

So, that's the drive system.

If you were interested in building a motion cockpit a good

place to start, and one which won't break the bank

instantly, might be to firstly build and get running the

Signal Processor Unit and then later tie it to speed

controllers and drive motors. The Motion Drive software and PICAXE chip programming are

avaiable

from this site, and the PICAXE Experimenter

kit and chips are fairly inexpensive. Note also that you

don't have to use all the outputs - you could use just the

Pitch and Roll DOF drives for a 2 rather than 3 DOF

system......

Question! How can

the system be modified to provide a 6-DOF drive? I think

probably quite straightforwardly - but that's a project for another day!

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at