The flight sim motion cockpit drive software and

control system was always going to be the biggest challenge

for me. Proprietary motion cue software for flight

simulators is probably available to buy. However the experience of other DIY

motion

platform builders encourages the view that at least having a

go at developing the drive software and control elements myself makes sense

as it would substantially reduce the cost of the overall

system. So

I've had a go at it.....

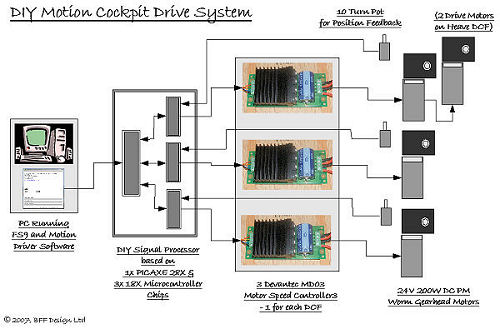

So what's in the DIY system?

(Schematic above - click for bigger image) -

System Now Updated - See HERE

-

At its front end is FS9

and my Motion Drive

software application running on the same PC.

The Motion Drive software is written in the

AutoHotKey (AHK)

scripting language and, with the aid of other free

utilities, pulls the detailed

aircraft flight motion parameters from FS2004, does the

math to determine the appropriate movement cues and sends them

down a serial port connection to a micro-controller

based Signal Processor unit. The cues are output

from the PC in the form of digital

position demand signals for each movement DOF.

-

There is a DIY

micro-controller based Signal Processor unit which

receives the digital position demands sent from the PC.

It also receives actual cockpit position feedback data from

multi-turn potentiometers on the moving

cockpit and using these two sets of data continuously

converts the digital position demand data from the

PC into analogue speed demand voltages needed

to control the drive

motors. These are output as three 0 to 5 Volt pulse

width modulated (PWM) variable voltage signals which

can be read directly by the high current motor speed controllers

to drive the motors for each DOF. The Signal Processor

unit is in effect a digital position to analogue speed

demand converter.

-

There are three proprietary

H-Bridge motor speed controllers which do the hard electrical

work of driving the electric motors. These control the speed

and direction of the motors as directed by the

Signal Processor units and handle the full drive currents

of the motors.

-

And finally there are

multi-turn potentiometers mounted on each drive motor

which provide feedback to the Signal Processor Unit,

this

tells it where each DOF actually is at any moment in

time - these are essential because they allow the

control system to decide in what direction and how fast

to run each motor to get the cockpit to move where the

Motion Drive software wants it.

There are other elements to

the system too, such as a 9V regulated power supply to power

the electronics and a 24V DC supply to power the motors but

those listed above are the main working elements.

The drive system has evolved

through a few variations in which I've changed or adjusted

all the main elements including the software, micro-controller

programming and the type of speed controllers used. It now performs

well considering it is a DIY build with very little delay between the

flight motions occurring in FS9 and the cockpit moving in

response. The Motion Drive software has been

structured to allow the programming of the motion cues to be

altered and updated - the motion cue programming

for each DOF is in the form of a separate AHK script. If you

know what you are doing this scripting can be customised in

the OpenSource version to

give the cues you are looking for if my programming attempts

don't suit you.

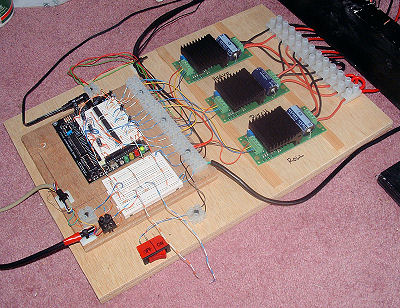

The

drive system has been relatively easy to build as it uses readily

available components and easy to work with bread-boarding

methods, electrical connections and wring. The high current

side is a 24V DC system so there are no direct mains

electricity connections and as such it represents a much

reduced electrical hazard.

The

drive system has been relatively easy to build as it uses readily

available components and easy to work with bread-boarding

methods, electrical connections and wring. The high current

side is a 24V DC system so there are no direct mains

electricity connections and as such it represents a much

reduced electrical hazard.

I've now managed to get the

drive system running fairly well. Changes to the motor speed

controllers have resulted in an electrically "quieter"

system in which the micro-controllers are stable and run

fairly reliably. Changes to the way in which data is read

from FS9 have resulted in a much faster data transfer rate

with new position demand signals now being sent to the drive

system every 60ms - about 18 sets per second. And changes to

the motion cue programming have given better cues and a

better set of programming tools for further development. It

is still a low cost DIY system however and will not be as

robust as paid-for commercial drives. In particular its high

frequency response is limited and demanded oscillations of

frequency much above 1 Hz start to be lost - room for

development!

Original SPU Design Original Overall Wiring

© This site is

copyrighted, If you'd like more information or have any

comments please contact me at